Paint Shop

With the automotive industry demanding higher performance, paint shop success depends on equipment that fits changing needs.

Automotive Manufacturing Solutions

Driving Durability & Loyalty

A perfect finish and sound seal not only insulate and make a vehicle look good; they drive durability and consumer loyalty. Improve the quality and efficiency of your automotive production with Graco paint shop solutions. Proven results include lower labor and material costs, and increased precision.

Seam Sealing

Sealing seals out dirt, corrosives, and water on the upper body, interior, and exterior of the car. Water ingression and corrosion protection need an optimized and repeatable process within the paint shop. Graco has a range of sealer pumps, metering systems, and applicators for manual and automatic processes, whatever size of material delivery containers you may have.

LASD & NVH Foam

Enhancing automotive comfort and refinement through advanced materials and processes, both Liquid Applied Sound Deadening (LASD) and NVH foam play pivotal roles in minimizing noise, vibration, and harshness (NVH) within vehicles.

Liquid Applied Sound Deadening (LASD) applied strategically to body panels, floor pans, and wheel wells, LASD coatings effectively dampen sound and vibration by converting mechanical energy into heat, thus reducing noise transmission into the cabin. With the ability to conform to complex shapes and seamlessly integrate into the assembly line through automated systems.

NVH foam is another option for combating undesirable noise and vibrations. Specifically engineered to absorb and dissipate sound waves and vibrations, NVH foam is strategically placed within vehicle cavities and structural components (pillars, cowl bars, rockers, wheel wells and sail panels) during assembly. By effectively dampening unwanted noise and vibrations, NVH foam significantly contributes to creating a quieter and more comfortable driving environment for passengers.

Anti-Chip

Anti-chip coatings offer a shield against the perils of road debris, gravel, and other abrasive materials. Applied to vulnerable areas such as the lower body panels, wheel arches, and rocker panels, these coatings provide an effective barrier against chipping, scratching, and surface damage.

Paint Circulation & Supply

The heart of every paint shop is the paint kitchen, where circulation and supply pumps serve as the lifeblood, ensuring the efficient and consistent delivery of paint materials throughout the production process.

The efficient operation of circulation and supply pumps is essential for achieving flawless paint finishes, reducing rework, and maximizing throughput in automotive painting operations. Their reliability and performance contribute significantly to the overall efficiency and success of paint shop operations in the automotive industry. Our electric and pneumatic pumps offer unmatched control over viscosity, color, and temperature, directly improving quality while cutting waste and costs. Designed for durability and quiet operation, these pumps allow for quick color changes, saving valuable time. Their high-performance motors handle a wide array of paints and coatings, ensuring your operations run smoothly and efficiently.

2K Proportioning

Controlling automotive interior noise levels is important. To create a quieter ride, many automotive manufacturers use acoustical foam to fill and seal roof pillars or other frame members that would otherwise transmit noise. The Graco NVH system easily allows you dispense acoustical foam into these cavities to prevent road, wind and engine noise from entering the cabin. Achieve lower costs and less re-work by using Graco’s proven HFR system for acoustical foams.

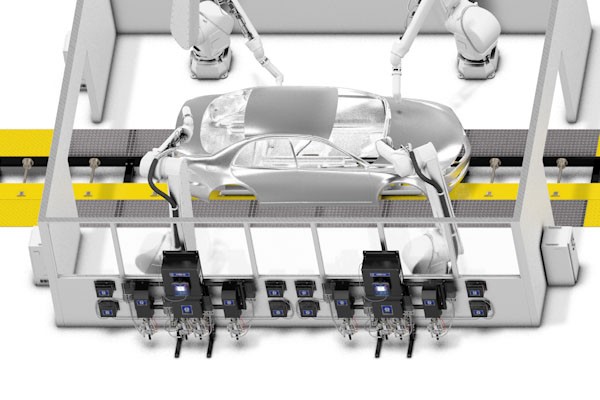

Manual & Automatic Spraying

Manual and automatic spraying techniques complement each other in automotive manufacturing paint shops, offering versatility, precision, and efficiency in achieving high-quality finishes on vehicles. Whether applied by skilled technicians or robotic systems, these techniques contribute to the aesthetic appeal, durability, and value of automotive products. With a wide choice of applicators, Graco is offering spray guns for all types of installation, both for spray booths equipped with automatic robots and for manual painting. Choose from a variety of technologies—air spray, air-assisted, airless, electrostatic, or rotary bell—to perfectly match your manufacturing requirements.

Spot Repair

Spot repair is a specialized technique utilized in automotive manufacturing to address minor imperfections and damages on vehicle surfaces. Whether it's a small scratch, chip, or blemish, spot repair allows manufacturers to quickly and efficiently restore the affected area to its original condition, ensuring a flawless finish. Graco spray guns ensure the color match and consistent quality required to expertly refinish defects, leaving a smooth, seamless finish.

Related Articles & Case Studies

White Paper

Unique Research Explains Subtle, but Costly, Automotive Finishing Challenge

An automotive factory paint shop suffered from inconsistent quality. Certain colors or metallics that provided high-end finishes sometimes went flat or lacked luster. The dull paint had to be flushed and discarded at great expense.

Why the costly waste? Industrial finishing experts uncovered the real problem.