Automotive Body Shop

With today’s advanced vehicle designs, where durability, performance, and safety are vital, OEMs and tiered suppliers are relying on Graco dispensing solutions for Body-in-White (BIW) applications.

Solutions for Automotive Manufacturing

Best-In-Class Performance

Sealants and adhesives are paramount as automotive manufacturing calls for lightweighting and improving structural integrity. Graco dispensing systems provide accurate material dispense in simplified systems to allow for greater design flexibility and reduced production costs.

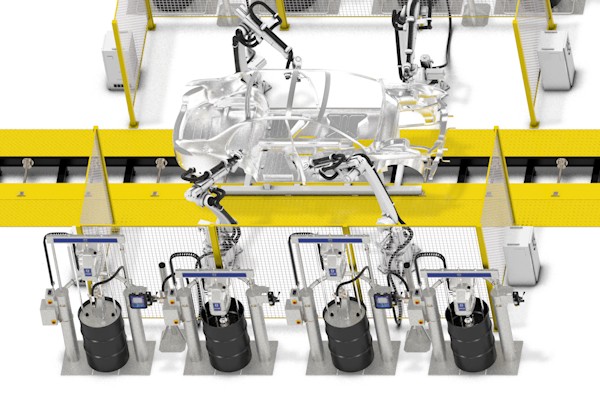

Meter From Drum Technology

E-Flo iQ Metering & Dispense System

For Body-In-White adhesive dispensing applications, the new E-Flo iQ Metering & Dispensing System delivers sustained in-plant performance, lowers maintenance costs, and drastically reduces system complexity, all without the need of an external metering device.

Structural Bonding

Automotive structural adhesive application has been growing in automotive body-in-white (BIW) applications because of ongoing requirements for vehicle weight reduction, increased safety, and increased reliability. High-strength adhesives, combined with mechanical joining methods, can increase an automotive structure’s rigidity, strength, and fatigue life. Along with more robust, stable structures, other benefits can also be obtained, such as decreased noise and vibration levels. Precision and accuracy are important to proper bonding and efficient material use. Metering systems with strong material control and robust equipment to handle highly abrasive, medium to viscosity material is recommended.

Anti-Flutter

Anti-flutter is an automotive closure application that bonds the inner and outer panels of car hoods, roofs, doors, and trunks to reduce vibrations or “fluttering.” Graco offers pumping and metering systems for manual applications or for automated applications, where it can be easily linked ot any robot.

Hemming

Hemming is the application where adhesive bonds inner and outer panel edges in automotive closures such as metal hoods, doors, trunks, or tailgates. This automotive panel bond of two thinner panels offers considerable weight savings over a single, thick panel. The precision of automotive hemming is essential to improve crash safety, prevent corrosion, and perfect appearance.

Related Articles

Automotive Structural Adhesives Application

Accurate bead placement is critical for a properly bonded system. Learn more about how E-Flo iQ delivers sustained in-plant performance, lowers maintenance costs, and drastically reduces system complexity for structural adhesive application.

Automotive Seam Sealing

Effective seam seals are important to prevent the intrusion of environmental factors into the joints of car bodies. Learn how to achieve efficiency and optimal dispensing speeds in this application.

Four Reasons Why Electric Motors Are the Greener Solution

Industrial manufacturing companies are moving from air to electric to reduce their costs and environmental footprint.

Comparing 1k Metering & Dispensing Systems

Shot size and flow rate, material properties, and manufacturing style are important when evaluating the correct metering system for single component sealants or adhesives.

Electric Motors Reduce Noise Pollution in Assembly Applications

The easiest way to reduce noise pollution -- and create a healthier working environment -- on a factory assembly line is to replace pneumatic motors with electric.

Anti Flutter Application for Body Shop Closures

Designed to protect the exterior of vehicles and reduce noise during operation, anti-flutter applications are an important step in the automotive assembly process.

Hem Flange Bond in Automotive Closure Assemblies

Hemming is considered one of the most challenging applications in automotive construction. Here’s what you need to know in order to improve crash safety, prevent corrosion, and perfect appearance.

Lightweighting in Manufacturing Processes

Lightweighting is a modernized, cost-effective manufacturing concept that is proving superior to old methods. Find out about additional benefits and how lightweighting can bring auto manufacturing to the next level.

Four Maintenance Advantages of Using Electric Motors for Assembly Applications

To power a pump, do you choose an electric or pneumatic motor? Here are the key maintenance considerations to choose electric.

Why Electric Motors Improve Quality and Precision of Dispense for 1k Metering

Electric motors have the capability to drive the pump lower more intelligently and therefore dispense an accurate bead without the need for an intermediate metering device.