Electronics Manufacturing Solutions

Sealing / Gasketing

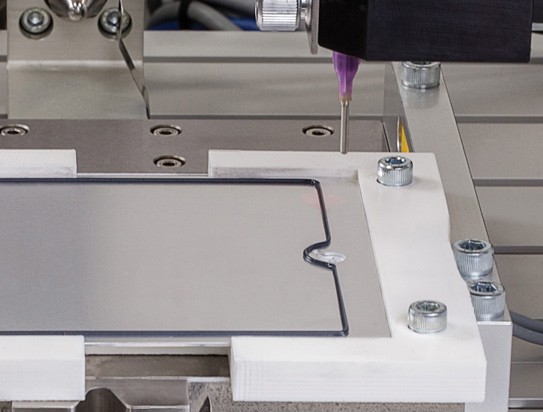

Dispense Solutions for Sealing and Gasketing

Sealing is the process of continuous bonding. Gasketing is the process of applying sealants.

Sealants are commonly applied around a perimeter using cure-in-place gasketing (CIPG) or form-in-place gasketing (FIPG). Either method provides a continuous liquid sealing surface between the housing and the cover to prevent dust and moisture from entering the interior of the unit and damaging sensitive components of electronics.

Sealants can be found in anything that needs protection from harsh environments like solar panels, tablets, or screens.

Related Articles

Warm-Applied Solar Panel Edge Sealant

A solar panel manufacturer improves its bead profile and application speed while removing quality issues related to the dispensed edge seal adhesive.

Solar Panel Edge Seal: Liquid-Applied vs. Tape

Uncover the advantages of pumpable solar edge tape (PSET) over traditional tape application methods for sealing solar panels.

Silicone Sealant for Solar Frame Attachment

Discover how a solar panel manufacturer improved bead profile consistency for solar frames using Graco automated silicone dispensing solutions.

Precision Dispense for Bonding and Sealing

When a product's functionality depends on a perfect bond or seal, dispensing an imperfect bead could lead to considerable cost implications.

Improved Sealing with Liquid Gaskets

Liquid gaskets offer superior sealing in a variety of applications

Comparing 2k Meter Mix Dispense Systems

Chart compares advanced two-component meter mix dispense (MMD) systems, including PR-X, PD44, PR70, EFR, and HFR.

Comparing 1k Metering & Dispensing Systems

Shot size and flow rate, material properties, and manufacturing style are important when evaluating the correct metering system for single component sealants or adhesives.

Related Materials

Common electronic sealants include silicones, polyurethanes, physical foaming materials, and mixed foaming materials.