Four Reasons Why Electric Motors Are the Greener Solution

To meet sustainability goals, many manufacturers moving from equipment powered by compressed air to solutions powered by electric motors.

1. Energy Savings

Moving from air to electric is a key strategy for industrial manufacturing companies to reduce costs and environmental footprint. Electric motors are more efficient and offer higher performance than their equivalent pneumatic motors. Many companies are phasing out pneumatic motors because they realize that air is the most expensive commodity in their plant.

2. Fast ROI

The return of investment for an electric-driven system is quite fast. This quick ROI can be directly attributed to its low maintenance needs and its high quality and precision of dispense.

3. Access to Actionable Information

Through the performance logs and digital nature of an electric motor, a wealth of information is available. This can be used to take actions externally and remotely through PLC control. It also means that electric motors become key components in your Industrial Internet of Things (IoT). This is not the case with pneumatic motors.

4. Reduced Noise

Air compressors and pneumatic pumps are generally extremely noisy creating environmental working concerns for operators. The systems and pressure pulses from compressors are quite severe, and noise levels can exceed 105 dB(A). Electric motors are quieter than pneumatic motors typically operating less than 70 dBa and will reduce noise levels in your industrial facility to create a healthier working environment.

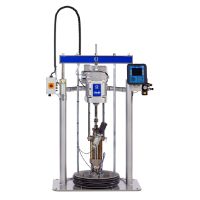

Electrically Driven Dispense Equipment

Electric sealant and adhesive dispense equipment that offers all the benefits described above include these popular products:

- E-Flo SP Electric Supply Pumps are designed for industrial and automotive sealant and adhesive applications. The advanced pump can drastically increase efficiency, improve system control capabilities, optimize process performance, and provide critical performance data.

- E-Flo iQ Metering and Dispensing Systems greatly simplify the robotic application of single component sealants and adhesives.

- Electric Fixed Ratio (EFR) Metering delivers accuracy, versatility and ease to plural component sealant and adhesive applications, especially those requiring consistent shots and beads.

Contact an Expert

Related Articles

Electrifying Your Industrial Process and Grow Your Bottom Line

Electrification of industrial processes is not only good for the environment, it makes good business sense. Explore how sustainable manufacturing leads to cost savings and competitive advantages.

Electric Motors Reduce Noise Pollution in Assembly Applications

The easiest way to reduce noise pollution -- and create a healthier working environment -- on a factory assembly line is to replace pneumatic motors with electric.

Four Maintenance Advantages of Using Electric Motors for Assembly Applications

To power a pump, do you choose an electric or pneumatic motor? Here are the key maintenance considerations to choose electric.