Bottler Achieves 45% Reduction in Hot Melt Adhesive Usage for End-of-Line Packaging

Since Refresco Iberia annually packages 1 million liters of soft drinks and juices, that is a lot of money.

Fidel Castello, operations manager; and Josep Ferri Sanz, engineering manager, explain how Refresco Iberia's end-of-line packaging line has achieved great savings with InvisiPac.

“Initially, we were talking about a 30% savings. But we reduced our hot melt adhesive usage by 45%.”

Since Refresco Iberia annually packages 1 million liters of soft drinks and juices, that is a lot of money.

How to Use 45% Less Hot Melt Adhesive and 40% Less Electricity

“We started out with two test units in one plant, now over 20 lines have been converted to InvisiPac," says Juan Manuel Pizarro, Graco’s packaging sales manager.

The set-up process was so smooth that one year after the installation, factory floor workers hardly remember the change.

This success was driven by Josep Ferri Sanz and Fidel Castello, who took the lead in optimizing packaging processes at Refresco Iberia.

In addition to achieving a 45% reduction in hot melt adhesive usage across all production lines, Sanz explains, “We significantly reduced our electricity consumption by 40%.

"InvisiPac has proven to be a valuable asset, not only lowering costs but also making operations easier for our team, with less maintenance required from our technicians.”

That is why Pizarro says, "We are currently setting up an action plan for other Refresco sites.”

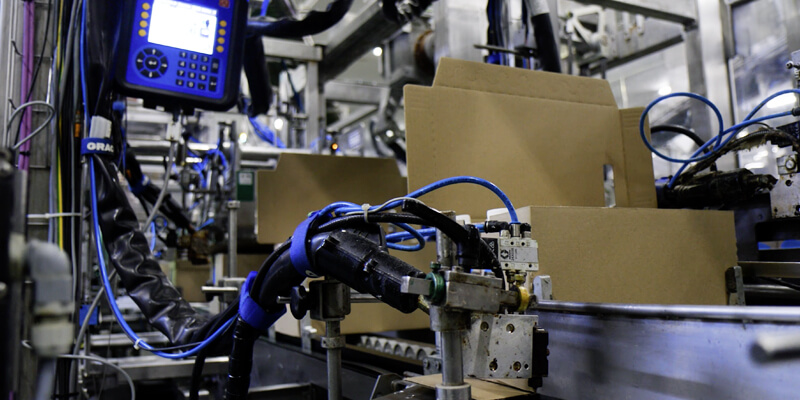

End-of-line packaging line at Refresco Iberia

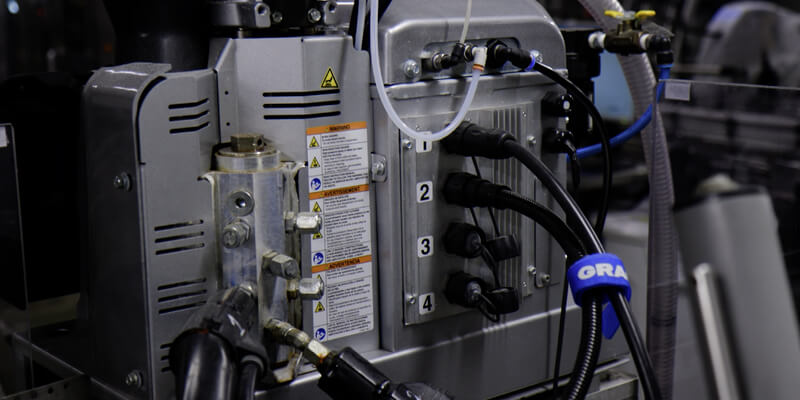

A look at an InvisiPac Hot Melt System setup on the Refresco Iberia packaging line

About Refresco

Refresco is the world's largest independent bottler of beverages, with production sites in Europe, North America and Mexico. They have over 80 factories worldwide.

InvisiPac advanced display module (ADM)

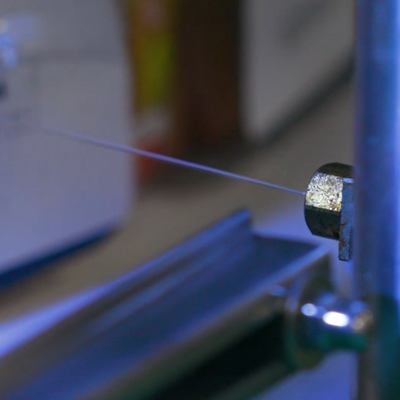

Hot melt adhesive being dispensed

All trademarks and registered trademarks are the property of their respective owners.

Make InvisiPac work for your cardboard packaging

InvisiPac is a melt-on-demand, tank-free adhesives system. It makes your end-of-line case and carton sealing faster, safer and more reliable and cost-effective.

With a true melt on demand principle, this hot melt delivery system eliminates adhesive char and improves productivity. InvisiPac has been proven to:

- Cut energy costs with 45 up to 72%, compared to other systems

- Reduce adhesive consumption by up to 50%

- Hugely reduce maintenance time and machine downtime

- Enhance operator safety by eliminating exposure to hot adhesive

- Greatly reduce the environmental impact of the hot melt system

Related Articles

Fruit Packager Seals Cardboard Boxes with 64% Less Glue

The hot melt delivery system for a large fruit packaging house was causing major problems. The packaging manager explains how InvisiPac reduced costs and liability issues.

Reduce Energy Consumption by 36 Percent

How much energy can be saved when dispensing hot melt adhesive with the InvisiPac HM10? An adhesive solutions company put Graco’s hot melt delivery system to the test for cardboard packaging.

Industrial Networking 101

How does equipment in a factory spray line, dispense line, or other assembly line know what to do and when? Get a birds-eye view of how industrial networking and automation works.