Solving Frozen Food Packaging Challenges

Avoid Case And Carton Pop-Opens

The Right Equipment for the Application

Frozen food packaging manufacturers want the same results as other case and carton sealing applications: a quality seal that stays in-place. However, realizing a successful end-of-line packaging process in frozen food manufacturing presents unique application challenges.

Three Steps To Reliable Frozen Food Packaging

In order to support an optimized manufacturing process in frozen food applications, it is important to understand how to:

1. Select the right adhesive product for the application

2. Maintain the correct adhesive temperature

3. Prevent operator intervention

Hot Melt Adhesives and Cold Environments

The processes involved with frozen food packaging create a production environment that is constantly changing. Certain frozen food packaging applications create specific challenges related to the particular circumstance. Products manufactured with a blast freezer demand very precise control of adhesive temperature to maintain the adhesive properties and deliver a quality seal.

For example, frozen waffles are typically bagged and placed into the carton in a cold room, then hot melt adhesive at 350°F (177°C) is applied to the carton flaps before going into the blast freezer. This transition represents a drastic temperature change – from a 40°F (5°C) environment to a -40°F (-40°C) environment in a very short period of time.

Consistent Adhesive Temperature

To achieve the performance needed to deliver a quality case and carton seal, it is critical to control the adhesive temperature. Inconsistencies with adhesive temperature lead to uncertainty around hot melt application effectiveness. Adhesives with temperature fluctuations may hold initially and stay intact leaving the plant, but may fail after product cartons sit for 24-48 hours at 0°F (-18°C).

The two most common causes of inconsistent adhesive temperature can often be linked to tank-based hot melt equipment and operator intervention. Maintaining a consistent adhesive temperature with tank-based hot melt systems typically requires line operators to constantly make temperature setting adjustments. Adhesive temperature swings are also common if operators let tank-based melters run low and then fill them with unmelted adhesive. Without the proper time to recover (upwards of 45 minutes), adhesive temperature may drop to 340°F (177°C) or lower – making the bond susceptible to failure.

More Aggressive Adhesives Can Increase Char

To overcome frozen food packaging issues, adhesive manufacturers have developed materials that are formulated to withstand temperature as cold as minus 40°F (-40°C) and will not degrade as quickly. This is appealing to frozen food manufacturers as more aggressive adhesives provide an added insurance policy to prevent pop-opens.

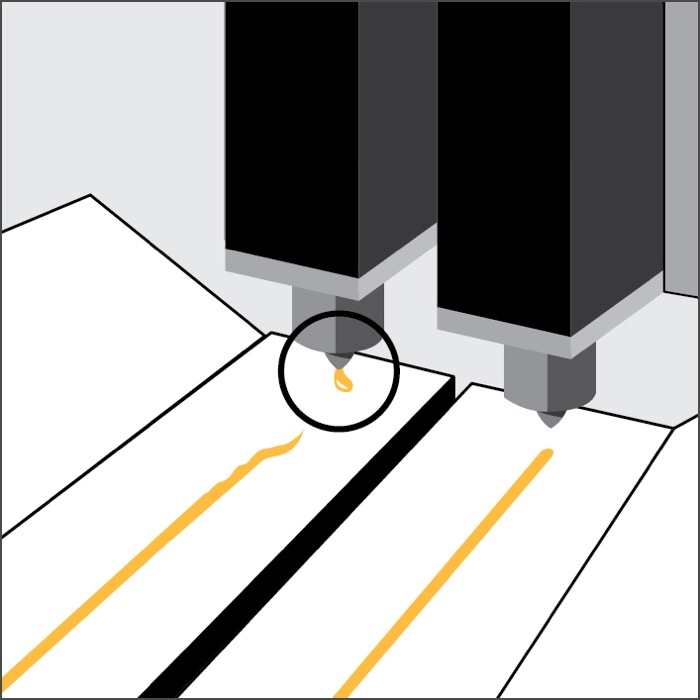

Unfortunately, increased char is a reality with some of these formulations. In general, the more aggressive the adhesive, the more quickly it will degrade under temperature. Manufacturers may also choose to make the glue hotter and tackier while also applying more adhesive than typically necessary. However, this is not a viable solution as it increases adhesive consumption, increases the likelihood of charring and nozzle plugs, and ultimately compromises the quality and consistency of the resulting seal.

New technology delivers consistency and reliability

Frozen food manufacturers will be able to achieve consistent case and carton sealing by using true Tank-FreeTM hot melt systems that include revolutionary melting chambers instead of inefficient heated tanks. The new technology in these systems:

1. Provides real melt-on-demand capability

2. Maintains consistent adhesive temperature

3. Maximizes adhesive stability and performance

Even if a more aggressive adhesive material is required, operators don’t have to worry about adjusting system settings to maintain temperature or avoid glue degradation. Since this technology melts adhesive on a “first in/first out” basis – so it melts the only glue that is needed, when it is needed. These benefits help frozen food manufacturers optimize adhesive performance.

It’s not always clear if a hot melt system is truly Tank-Free. Some equipment suppliers market their equipment as “tank-less”. Before purchasing a new hot melt system, be sure to ask the equipment supplier these six important questions.

Related Articles

6 Reasons to Choose InvisiPac

Graco’s InvisiPac® Tank-Free™ Hot Melt System utilizes disruptive technology to optimize the case and carton sealing process for manufacturers. Here’s why packaging lines use InvisiPac.

Beer Packaging Line Ends Backups and Downtime

Summit Brewing Company's packaging manager shares how “we have almost no downtime” with a new tank-free system.

Choosing a Hot Melt Nozzle

Tips for selecting the right hot melt adhesive nozzle based on your specific application.