Choosing a Hot Melt Nozzle

Hot Melt Nozzles Impact Performance

Selection and Performance Tips

Selecting the right nozzles for your hot melt equipment can have a big impact on achieving throughput and performance targets with hot melt adhesive systems in end-of-line packaging operations. In order to make the right choice, there are three main factors to consider and evaluate:

· Understand Hot Melt Material Properties

· Know What Makes Your Application Unique

· Identify Maintenance Program & Goals

What Are Hot Melt Nozzles?

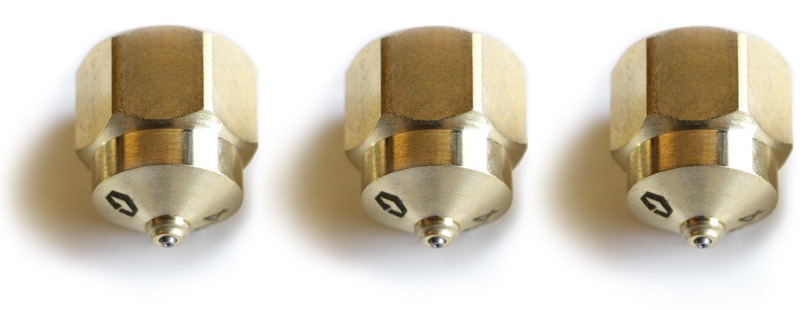

Once hot melt adhesive has passed through the heating process, the molten adhesive is transferred to the applicator or “gun” for dispensing. Located at the very end of the gun, hot melt nozzles ultimately control the volume, velocity and direction of the dispensed adhesive.

These nozzles are interchangeable and are manufactured in multiple sizes and designs for a variety of dispense applications. Most nozzles fit into the following categories:

· Bead – provide a single continuous bead or patterns

· Spray – dispense in patterns at various widths and diameters

· Multi-line – deliver multiple beads and patterns from a single nozzle

As part of a hot melt adhesive system, hot melt nozzles play a significant role in helping avoid waste and improve efficiency. When determining the effective hot melt nozzle diameter, a common misperception is that bigger is better to avoid downtime from nozzle plugs and keep the production line moving. While this approach may provide a short-term gain, it is important to understand that orifice size does not directly correlate to the amount of glue dispensed.

The limitations of the hot melt equipment should never dictate hot melt nozzle specification but unfortunately it does. It is common for manufacturers and maintenance managers to view hot melt nozzles as a consumable. However, the nozzles directly affect the performance/pump life of some hot melt systems.

Understand Material Properties

With hundreds of hot melt adhesives available, the first step in selecting the right hot melt nozzle for optimum performance is to understand the characteristics of the hot melt adhesive material itself. Even within the same manufacturer product line, hot melt adhesive properties vary. For example, the viscosity of an EVA hot melt adhesive may be 1100 centipoise @ 350 degrees where a metallocene hot melt may have a thinner 700-900 centipoise at the same temperature.

The performance of the hot melt adhesive will have an impact on the performance of the hot melt adhesive system. This will be most noticeable at the point of dispense – the hot melt nozzles. A best practice would be to involve your material supplier when optimizing hot melt equipment and specifying nozzles.

Hot melt adhesive pellets

Know Your Application & What Makes It Unique

While there are common themes to most end-of-line packaging and case and carton sealing applications, every application is unique. From the finished goods inside, the carton stock, marketing display elements, line speed and glue throughput, each application has elements that must be taken into account when specifying hot melt nozzles.

Some application elements that effect nozzle selection include:

Nozzle Engagement: The Length Of The Nozzle Orifice Hole

As engagement increases the flow of adhesive decreases

Nozzle Orientation/Dispense Pattern Requirements

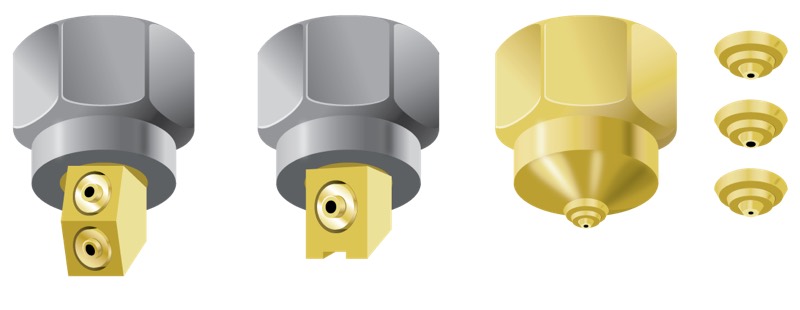

1) Single orifice:

- Straight or 90 degree angle

2) Multiple orifice:

- Dual orifice right angle: 15 or 30 degrees

- Three orifice: right angle: 19 or 22.5 degrees

- 2-4 orifice dome/mini button: 15, 20, 30, 45, 60 or 90 degrees

- 1-2 orifice dome/mini button offset: 15,30, 45, 60 degrees

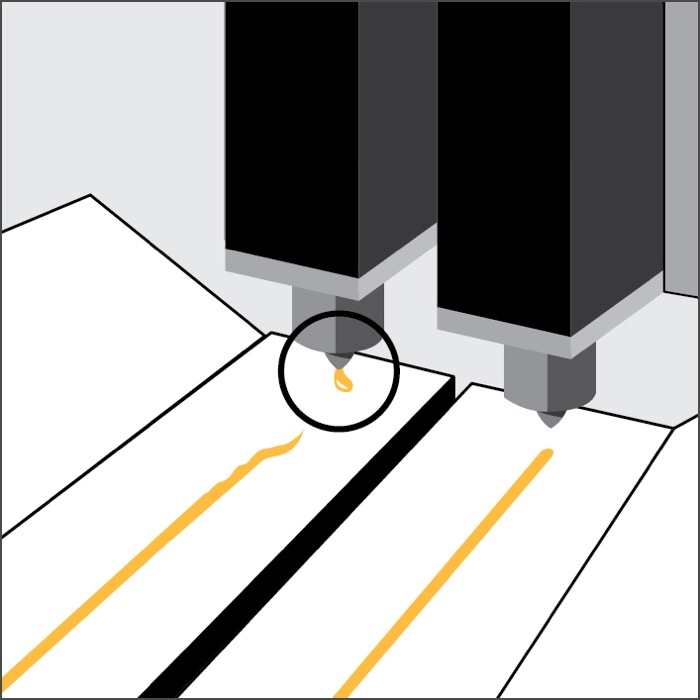

Clean Cutoff Requirements

1) Avoid adhesive stringing or “angel hair” build up

2) Eliminate scrap

Air Pressure

1) Hose length effecting pressure fluctuations

2) Effects on fluid dynamics

Velocity

1) Higher back pressure with smaller nozzles

2) Provides more powerful stream of adhesive to carry further

Pump pressure capabilities and fluctuations

1) Air-powered piston pumps

- High, consistent pressure

- Ability to support variety of nozzle orientations

2) Electric-powered gear pump

- Low pressure, continuous flow

- Lack of pressure dictates larger nozzles (.018-.24 or larger)

- Limits orientation options – hard to dispense other than top down

Single And Multiple-Orifice Considerations

It is common to see an application where multi-orifice nozzles have been avoided because of low performance, carton pop-opens after leaving the manufacturing facility, and concerns for potential downtime issues.

Another common mistake is when multi-orifice and single-orifice nozzles have been unnecessarily oversized to avoid nozzle plugs, rather than because either is the right nozzle for the application. Regardless of when this occurs (when setting up the line or implemented over time), it is always best to specify nozzles for the application rather than limitations of the hot melt system and equipment dictating nozzle selection.

Identify Maintenance Program & Goals

Regardless of the nozzle selection, one constant to maintain throughput and uptime is the need to clean and maintain the nozzle. Adhesive char is a common problem for end-of-line packaging systems and is the biggest foe for hot melt nozzle performance.

It is not uncommon for maintenance to extend the nozzle life or reuse nozzles by using hole pricks or small drill bits to keep hot melt nozzles open. While this may be a short-term solution to keep adhesive flowing, this approach will often increase the nozzle orifice size and lead to higher adhesive costs. Identifying and confirming maintenance parameters with equipment suppliers will help maintain optimum performance without increasing material or spare parts costs.

Unwanted downtime and the issues that come with it can be avoided. Even in manufacturing environments with poor air quality and higher probability of contaminants entering into the hot melt adhesive, selecting hot melt equipment and nozzles that provide the highest amount of filtration can reduce downtime incidents by preventing contaminants from clogging nozzles. Some systems and nozzles are engineered to provide “zero plugs”.

When possible, ask equipment manufacturers for proof of these claims and see if a demo program is available. The ability to see the equipment performing in the actual environment will help validate how their technology can improve issues with unplanned downtime related to maintenance issues.

Ultimately, correct nozzle selection has a direct influence on material management, operating expense and operator safety. Make sure to have a detailed understanding of hot melt adhesive materials, the unique demands of the application and the maintenance requirements to specify the right hot melt nozzles that will have the greatest impact on improving performance and production efficiency.

Related Articles

6 Reasons to Choose InvisiPac

Graco’s InvisiPac® Tank-Free™ Hot Melt System utilizes disruptive technology to optimize the case and carton sealing process for manufacturers. Here’s why packaging lines use InvisiPac.

Beer Packaging Line Ends Backups and Downtime

Summit Brewing Company's packaging manager shares how “we have almost no downtime” with a new tank-free system.

Comparing the Operation of Hot Melt Systems

Comparing how tank-based, tank-less, and Tank-Free systems work at each step of the hot melt process can help you determine which technology best suits your packaging operation.