Slurry Dispense for Electrode Coating

Growing Demand for EV Batteries

Growing demand for EV Battery manufacturing requires advanced solutions in the production of cylindrical Li-ion batteries – and slot die slurry dispense application is no different; it requires intelligent and high-performance equipment.

Rheological Changes

Slurry materials are non-Newtonian, meaning they are subject to rheological changes as materials are supplied from containers, through hoses, and other dispense system components. Slurry dispense creates challenges like shearing and changes in viscosity, yet the main challenges become thorough mixing and no dissolution of particles, a tough to control coating process, low uniformity of film thickness, and cracking of the material surface.

Density & Viscosity Control

Due to rheological changes and process challenges, slurry applications require the ability to control density and viscosity. Material rheological properties affect important attributes such as slurry stability, how easily materials mix, and coating performance – ultimately impacting your finished electrodes. It is necessary to have accurate and repeatable pressure and flow through the dispense equipment to achieve the desired density, viscosity, and maximum homogeneity without breakup of particles. Over shearing the material during processing can impact finished electrodes and lead to future concerns such as cracking from processing or environmental conditions, ultimately causing degradation in the performance of the battery.

Supply to Dispense

At Graco, we address these critical process challenges by providing a supply-to-dispense solution that has an Electrode Coating in mind. Traditional pneumatic supply systems can only provide pressure control, without the intelligence to react to drastic changes in viscosity, and an inability to adjust flow rates for shear sensitive slurry materials. Our Graco E-Flo SP Electric Pumps have the intelligence needed to maintain optimal pressure and flow rates that allow operators more control over the tolerances of different slurry materials. When combined with our PCF (Precision Continuous Flow) closed-loop metering system, hoses and iQ Dispense Valves, you have a complete continuous flow solution for a more uniform coating.

Other system benefits include:

- Improve mixing by supplying proper distribution of material contents with maximum homogeneity (Density & Viscosity control; supports material cost savings by creating less waste)

- Homogeneous coating thickness and greater control over process (Viscosity Control; supports control over battery lifetime)

- Supply to dispense solution improves overall homogeneity that sustains material properties (Density & Viscosity control; Control over Battery Discharge Capacity)

- Consistent material flow through closed-loop technology

- Adjusts for changes in material temperatures, viscosities, dispense rates and robot speeds

- Accurate and repeatable dispense

- Data downloads - process data and job logs

- Easy integration into automation

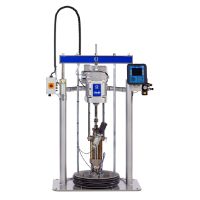

Equipment

To Serve Multiple Dispense Points:

- E-Flo SP

- PCF Metering System, with up to four (4) fluid plates

- iQ Valve - Tip Seal

Contact an Expert

Related Articles

Foam Encapsulation of Cylindrical Cells

Careful attention to thermal management and foam encapsulation are important to manufacturing high-performance battery modules that remain safe in any circumstance.

Comparing 2k Meter Mix Dispense Systems

Chart compares advanced two-component meter mix dispense (MMD) systems, including PR-X, PD44, PR70, EFR, and HFR.

Comparing 1k Metering & Dispensing Systems

Shot size and flow rate, material properties, and manufacturing style are important when evaluating the correct metering system for single component sealants or adhesives.