How to reduce industrial noise pollution with electric pumps

Air-operated double diaphragm pumps (AODDs) and especially air compressors exceed the noise standard for production environments. This is bad for your colleagues’ health, safety and productivity. Switching to electric solutions like Graco’s QUANTM pump is a logical step to reduce industrial noise pollution.

Industrial noise pollution

Industrial machinery and industrial processes in general come with a certain level of noise. The bigger the machines and the heavier the processes, the more decibels they tend to produce.

A noisy production environment has several downsides. Too much factory noise can make it hard for your colleagues to work together – causing miscommunication or even unsafe situations.

But it’s also bad for the wellbeing of those same colleagues. It’s no treat to work in a place where the machinery is overwhelmingly loud. And even worse: it can cause hearing problems or other health issues.

OSHA noise standards: 85 dB is the threshold

The Occupational Safety and Health Administration (OSHA) has set specific regulations to protect workers from exposure to hazardous noise. According to OSHA, the permissible exposure limit (PEL) for noise is 85 decibels (dB) averaged over an 8-hour workday.

Prolonged exposure to noise levels above 85 dB can lead to hearing damage. Occupational hearing loss is one of the most common work-related injuries and is permanent, according to the National Institute for Occupational Safety and Health (NIOSH). The US Centers for Disease Control and Prevention (CDC) estimates that 22 million workers encounter potentially harmful noise levels at work every year.

This makes it crucial for factories to address the safety hazard.

Industrial machinery used within production facilities is one of the largest contributors to hazardous noise levels and serves as a great place to start when looking to improve plant safety.

Motor and pump noise levels

Noisy pumps are a significant part of the problem. Or let us rephrase that: pneumatic pumps, often AODDs, are the usual suspects. Electric operated double diaphragm (EODD) pumps, on the other hand, can play an important role in industrial noise reduction.

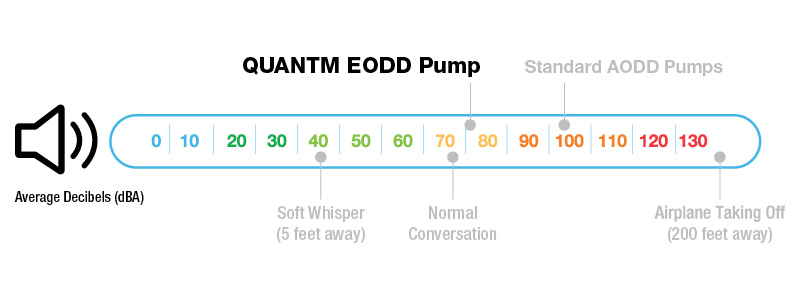

Let’s see where AODDs and electric pumps are on the decibel chart.

Pneumatic Motor Noise

Air motors are often sources of significant industrial noise pollution. These motors can produce noise levels ranging from 85 to 115 dB, depending on their design and operating conditions. Pneumatic diaphragm pumps in industrial settings are typically around 100 dB.

Air Compressor Noise

Air compressors are vital to power pneumatic pumps, but they are another major source of noise pollution due to air intake, exhaust, and mechanical vibrations. The sound pressure pulses exceed 105 dB and the outlet air even reaches levels up to 115 dB.

Electric Motor Noise

Electric motors generally produce less noise compared to pneumatic motors. The lower noise levels are due to the absence of combustion processes and fewer moving parts, which reduces vibration and mechanical noise. Graco’s QUANTM EODD clocks in at 74 dB.

How to reduce industrial noise pollution: electric vs pneumatic

Let’s put the numbers into perspective.

The sound that results from the rapid expansion of compressed air in a pneumatic pump is further amplified by the pump housing. And when numerous AODD pumps are installed next to each other, the sound can be deafening… literally.

It goes without saying that the most effective way to reduce factory noise is to eliminate the source of it, but obviously we still need pumps to move material through the process. When elimination is not possible, substituting loud equipment with quieter alternatives is the next best option to minimize noise levels and protect workers from hazardous noise.

Producing roughly 100 dB of noise, AODD pumps and air compressors far surpass the safety threshold of 85 dB(A). And at 74 dB of noise, QUANTM EODD pumps sit about 10 dB below the threshold helping to prevent potential hearing damage due to prolonged exposure

So how exactly does this apply when you switch out an AODD with Graco’s QUANTM pump?

Reduce industrial noise pollution with QUANTM electric pumps

Relying on AODD pumps means you are dealing with two noise sources — the pumps themselves as well as the air compressor. Replacing your AODDs with QUANTM pumps enables you to reduce the load on your compressed air system, or even get rid of it entirely, removing one of the two sources above.

QUANTM electric double diaphragm pumps eliminate the need for gear reduction and do not require a separate control or VFD. This provides the pump a compact footprint, nearly identical to air-operated double diaphragm pumps. This means you can easily retrofit your existing technology with a quieter and more efficient solution.

By eliminating compressed air from the pumping process, QUANTM EODD pumps can achieve a reduction in sound pressure of around 25%.

Conclusion

Selecting the best technology for your production facility is a crucial aspect of reducing industrial noise pollution and improving worker safety in your plant. Noise reduction is only one of numerous reasons why companies like yours are implementing electrification strategies.

Most electric technologies on the market today drive significant noise reduction. This is often paired with other advanced features that further contribute to improved environmental, health and safety measures.

Graco changed the game in diaphragm pump technology when it released the QUANTM series of fully electric double diaphragm pumps. Its revolutionary electric drive provides a quieter and safer solution than traditional air-operated units. Find out what makes QUANTM quieter and more energy efficient than its counterparts.

Now is the right time to make your company a better, healthier and safer place to work.

Interested in going electric?

- Get in touch with our experts

For more information about glue applications and the pumps being used in those applications, fill in the contact form and one of our experts will contact you shortly.

- Calculate your savings

In three easy questions, calculate how much you could save by converting your

facility to Graco electric double diaphragm pumps

Contact an expert

Related Articles

Electric pumps lead the way to energy efficiency and sustainability goals

Electric pumps lead the way to energy efficiency and sustainability goals

New technologies cut costs

Pumping systems are an essential part of manufacturing operations, many of which are powered by compressed air and consume large amounts of energy. As companies seek to build electrification strategies, QUANTM pumps provide a solution to replace inefficient technologies with a more sustainable trans...

Sustainable paths to profitability

Energy savings and sustainability are becoming profit drivers for companies around the world. Graco can help you build a cost-saving strategy and explore incentive programs to improve efficiency of processing technologies.