EV Battery Design: From Process to Production

Subtle design problems often derail production as electric vehicle (EV) battery manufacturers race to meet market demands. Graco’s eMobility strategist answers questions about ways to keep that process on track.

Questions and Answers about Manufacturability

Electrification is really taking off in the automotive industry. Do you see this as a trend or a long-term standard? Why?

We are seeing trends in electric vehicle (EV) production that are leading to standardization in battery designs and manufacturing processes. We’re also seeing different countries adopting environmental regulations that promote sustainability. Both factors play a huge role in making sure that electrification and EVs are here to stay.

There many iterations in the manufacturing of the battery in and of itself. The customers we work with are trying to figure out how to standardize for long-term growth.

How can battery design extend or add risk to ramp-up timelines for EV manufacturing?

There are decisions that you can make during the design phase of the battery itself that would reduce the risk in your timeline being pushed out. You need to consider what application process would be required to assemble the actual module or battery pack.

In an application like cell to carrier, for instance, the material you're using may have a cure time that affects cycle time. It could require a complex dispense or integration system to actually complete a module or a battery pack in the cycle time that you'd like.

As you think about ramping up in the next six months, for example, battery design engineers need to ask questions like these:

- How does the battery I'm designing -- the way it's being composed -- impact the type of equipment that I will use?

- How does it limit the type of equipment I can use?

- Could the complexity of the integration process – the dispense points or stations that I add – push out the timeline to production?

- Would doing this or changing that help in my production environment?

What battery design problems do you often troubleshoot?

A critical application that’s tied to the safety of passenger vehicles is battery encapsulation. The earlier your battery designers consider encapsulation, the better.

You're using thermal interface materials that must be applied in such a manner that would give you proper thermal conductivity. To effectively mitigate fire risks or thermal propagation, the foam needs to essentially level itself at the base of the of the battery module or pack, and then rise up through the battery.

The fluid dynamics and how your battery is assembled affect where the foam application injection point should be. You may need to change the cover of the module or the base of where the cells are to do a bottom injection. Or maybe an open pour application, where we pour the foam on top of the cell so that it goes down and rises back up right, would work better.

How do you see the shift towards battery recyclability impacting the application of adhesive and potting materials in battery design?

We’ve worked with companies that are looking at recyclability, but I can't say that many OEMs (original equipment manufacturers) are designing batteries in such a manner would lead to recyclability. It's usually other companies trying to figure out how to recycle them. And it's not their battery. So they're dealing with a design that didn't have recyclability in mind.

It's something that we definitely want to solve for. Since every design is different, every application has been different. For example, if you want to recycle a foam encapsulated battery pack or module, you need to keep in mind that a punctured cell can release gas at eight liters per second. That could be a lot of thermal propagation. To recycle safely, you’re going to have to clean off the material without damaging battery cells.

How can their chemistries effectively adhere when we need them to, but be easily removed without damaging the battery? That is a big challenge for material manufacturers.

What is unique about Graco’s approach to EV battery design?

Every battery design is different, and every battery itself is unique. But when it comes to the applications and the function of those applications within each battery pack, there are a lot of similarities.

The people in our eMobility group are hyper focused on understanding, not just fluid dynamics, but also each battery design. We've seen so many battery designs and many applications that we can pull from our pool of knowledge to actually give better meaning to what you're trying to do. This essentially helps cut down your learning curve, so that you can more quickly get to where you want to go.

Free Webinar Series

EV Battery Design for Manufacturability

Explore simple things EV battery designers and manufacturers can do now to prevent complications later during WeAutomotive’s free, two-part series with Robert Delgado, Graco's global market strategist for e-Mobility.

CONTACT EV BATTERY EXPERTS

Related Articles

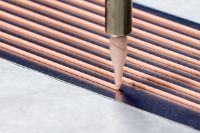

Cell to Carrier Bonding - EV Battery

Learn how to achieve cost reduction in battery assembly by shortening cycle times and contributing to high speed, automated processes.

Foam Encapsulation of Cylindrical Cells

Careful attention to thermal management and foam encapsulation are important to manufacturing high-performance battery modules that remain safe in any circumstance.

Pressure Sensitive Adhesives in EV Batteries

PSAs bring good adhesion and flexibility to cell to pack and pouch cell lamination. Move those applications into production with five questions about hot melt equipment.