Factory Keeps EV Battery Pack and Module Production Moving

Electric vehicle (EV) battery performance and safety depend on good thermal management. Thermal interface materials (TIMs) effectively dissipate heat from all parts of the EV battery pack, from the cells to cooling plates.

Yet, TIMs often cause production headaches on EV battery assembly lines. Such was the case for a large, multinational automotive manufacturer.

Gap Filler Challenges Accuracy and Equipment Life

The automaker needed to quickly dispense several kilograms of two-component thermal interface material (TIM) into EV battery packs. However, the highly abrasive gap filler often packed out and clogged fluid paths in their equipment.

Frequent fluid path clogging under high pressure not only affected accuracy and quality, it also caused frequent equipment shutdown for service.

The manufacturer subsequently asked Graco’s Asia Pacific team to help a factory in India deal with TIMs dispensing challenges. They needed a reliable solution that fit these production requirements:

- Allow a wide range of bead sizes — from 0.1 cc to 50 cc.

- Maintain fast production speeds, with flow rates in excess of 10 cc/s.

- A dependable, energy-saving system.

Process Identifies TIMs Dispense Solution

Graco application specialists worked with the factory’s EV battery assembly line engineers to identify production pain points and testing parameters. At the end of the process, dispensing systems strengthened with ELITE CONSTRUCTION™ were proven to meet their needs.

What is Elite™ Construction?

Abrasion-Resistant Systems

The factory’s TIMs dispense solution for EV battery pack and module assembly includes these Graco systems – all with abrasion-resistant Elite™ construction.

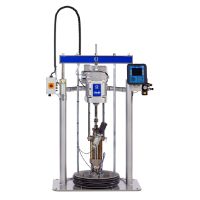

E-Flo SP Electric Supply Pumps have electric motors that operate at the mild and desired pressure, preventing TIMs from packing out or clogging the fluid path. The system eliminates the need for a regulator, further reducing the risk of clogging, and does not use compressed air, bringing significant energy savings and noise reductions. Stable pressure and smooth changeovers result in consistent beads without snake heads and tails.

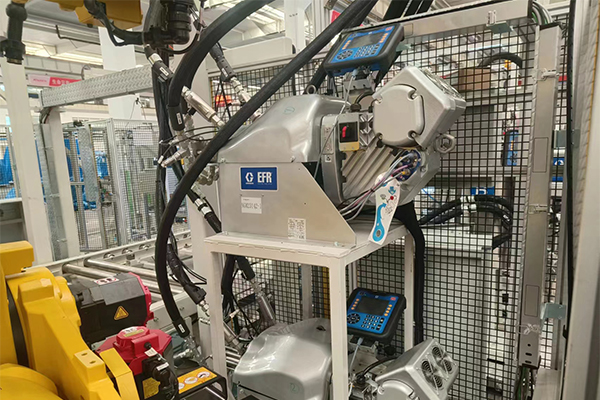

Electric Fixed Ratio (EFRTM) metering delivers continuous-flow dispensing that meets the production cycle rate for large shot sizes. The high-precision metering system is known for its excellent repeatability.

PR-Xv Variable Ratio Solution includes a patented first-in-first-out (FIFO) fluid path design that keeps thermal interface material from clogging hoses. With a minimum flow of 0.03 cc, the Posi-Ratio® system easily allows 0.1 cc. bead sizes. Its base purge function conserves material and keeps it from curing so that mixers do not need to be replaced frequently.

* Results may vary. Variables affecting component life include but are not limited to, material chemistry/fillers, flow rate, cycle rate, maintenance diligence, and system pressure.

Better Production Performance and Less Downtime

With Elite™ construction reinforcing the EV battery pack and module production, the automotive factory in India soon experienced these assembly line improvements:

- Equipment keeps dispensing a wide range of bead sizes without getting clogged up.

- Flow rates in excess of 10 cc/s keep production moving with little interruption to service equipment.

- The electric system eliminates the need of a regulator, thus reducing the risk of clogging and saving the time of cleaning up the regulator every week.

Contact TIMs Dispense Experts

For successful dispensing of thermal interface materials (TIMs) and other highly abrasive fillers, manufacturers need durable, stable, and reliable systems.

With years of experience, Graco experts can configure wear-resistant solutions, from supply to metering to valve. Contact us about total solutions for your TIMs dispensing needs.

Related Resources

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite™, the longest-lasting pump construction for abrasive material dispense.

Thermal Management (Gap Filler)

Thermal management dissipates excessive heat away from a part, so that it functions properly and does not combust. In electric vehicle (EV) batteries, thermal management usually involves gap fillers or thermal interface materials (TIMs).

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite™, the longest-lasting pump construction for abrasive material dispense.