Automotive Manufacturer Finds A Superior and More Economical Dispensing Solution

When an automotive manufacturer discovered a bottleneck in production, we discovered a versatile and flexible dispensing solution that did not sacrifice price.

Background

In the rapidly evolving landscape of e-mobility, a leading automotive manufacturer encountered a bottleneck: they required a dispensing system as dynamic as their production demands. The search for a solution led them to Graco.

The Challenge

The need was clear—develop a dispensing system that was not just efficient but also versatile and flexible enough to navigate through multiple dispensing tasks without sacrificing performance. Mobility within the plant was crucial, and so was the precision in dispensing dual-component sealants and adhesives.

Our Approach

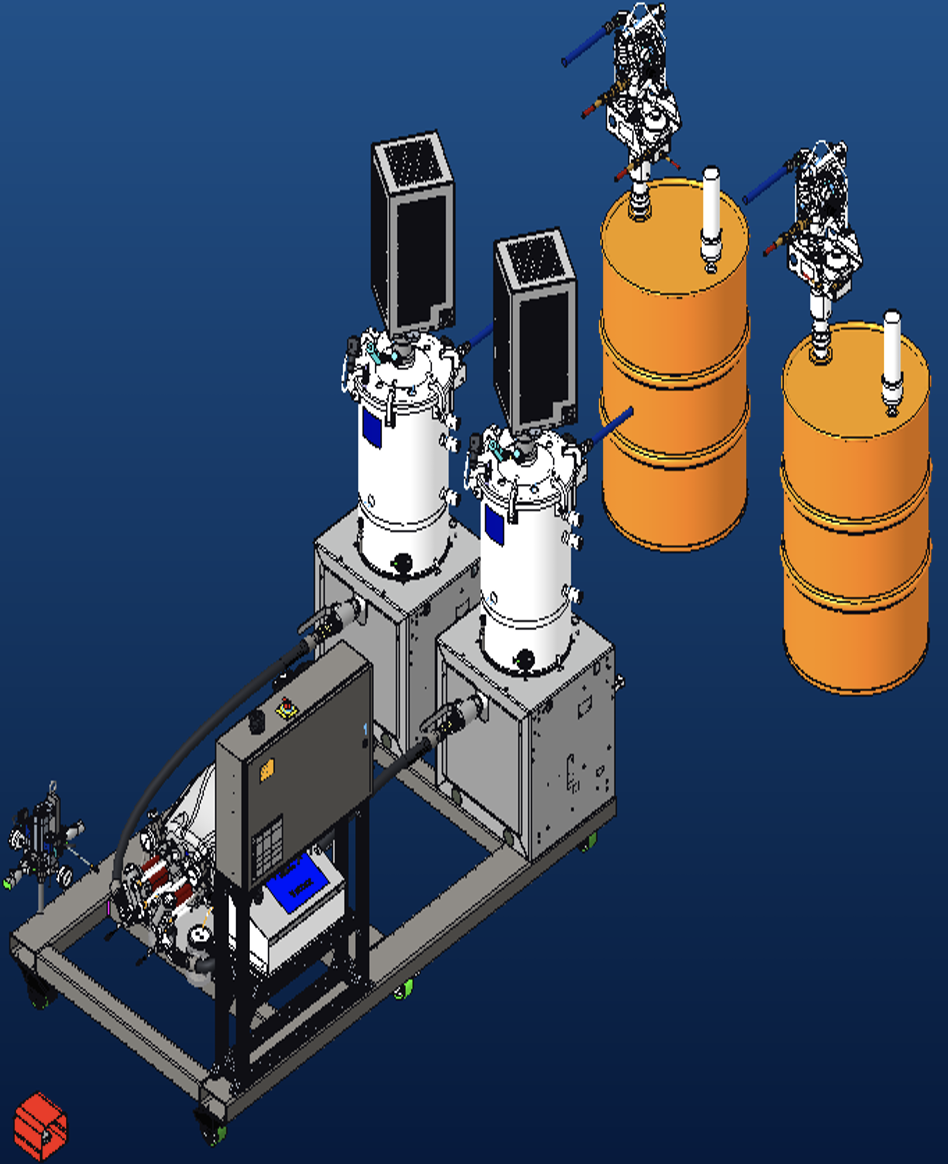

Through a series of collaborative sessions, we were able to distill what the client envisioned into a concrete, actionable design blueprint. The result was a flexible EFR (Electric Fixed Ratio) system. This custom-engineered unit combined all of the right components, mounted on a frame that could be moved where it was needed within the customer’s factory.

- EFR (Electric Fixed Ratio) System: an electrically-driven proportioner for two-component sealant and adhesives, ensuring consistent dosing of sealants and adhesives.

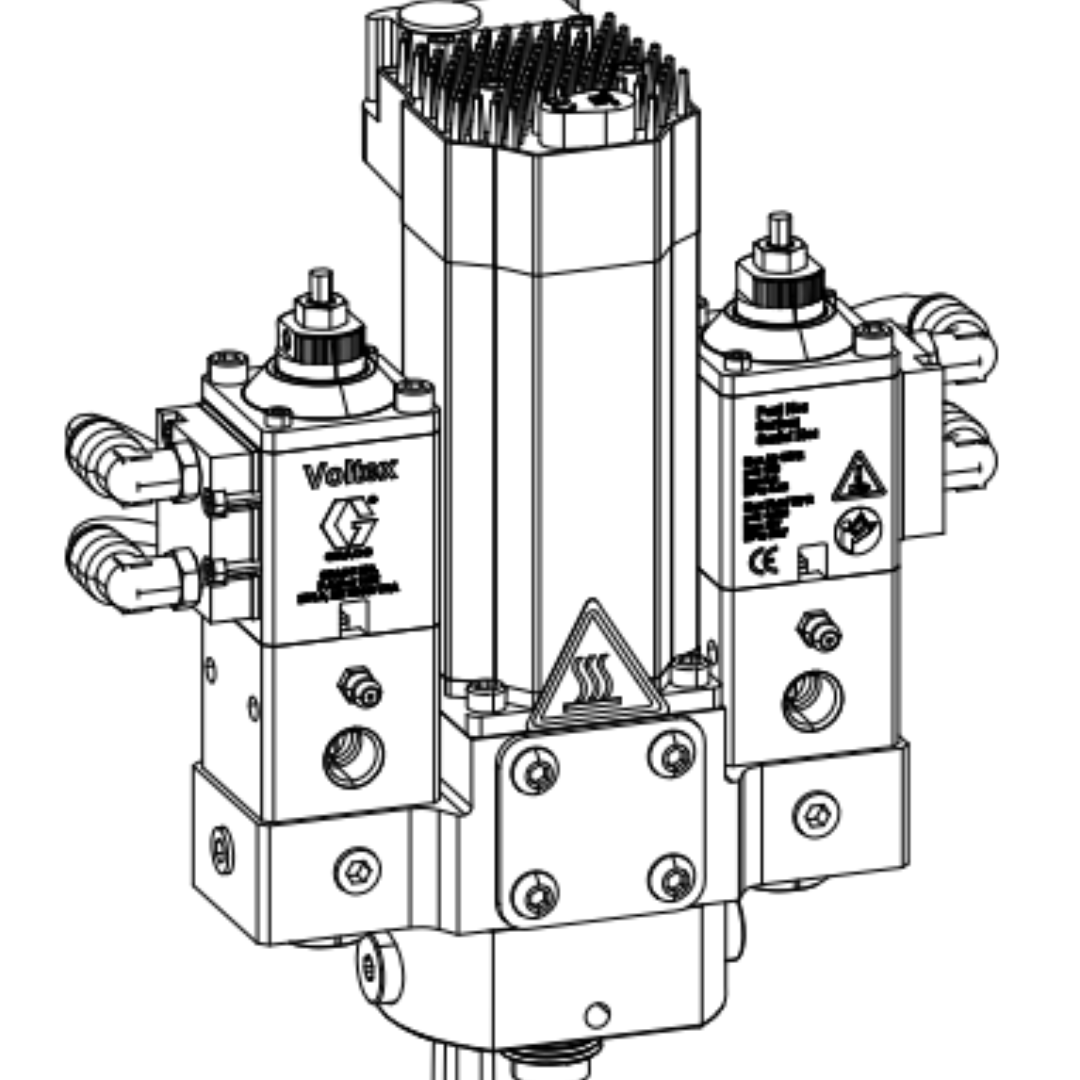

- Voltex DMV (dynamic mix valve): Dispense valve with rotary mixing element that consistently mixes and dispenses materials requiring exceptional mixing energy.

- Two 38-liter stainless steel tanks with agitation

- Husky diaphragm pumps with Twistork agitators for refill

- Custom-designed frame designed for mobility, housing a power distribution enclosure for a single power drop

- A portable unit, focused on minimizing footprint while maximizing portability.

Integration and Control

The Graco EFR system emerged as proof of precision, delivering consistent shots and beads. The revamped Voltex DMV became the heart of the system, directing the flow and dynamically mixing materials. The Voltex was customized to be hung from a counterbalance and trigger actuated. A custom single pneumatic drop was engineered for five air inlets for various devices. For additional flexibility, the unit was powered into a single point of control, ensuring a streamlined operation.

Integration and Control:

- Custom frame to distribute the weight for the required components

- Custom power distribution box for a single power drop for 4 loads

- Custom single pneumatic drop for 5 components

- Custom manual Voltex (DMV) hung from a counterbalance, with actuated trigger and handle

Outcome

With a fast-track engineering-to-shipment sprint, Graco engineered and built a new custom system for the customer, that was versatile and flexible enough to navigate through multiple dispensing tasks without sacrificing performance.

Discover the Graco Difference

Experience the collaboration of customer-centric engineering and state-of-the-art technology. Connect with Graco to explore this EFR system and other custom-made solutions designed to propel your production into the future.

Collaborate with Us

Innovation truly comes through collaboration with Graco expertise and customer partnerships. We strive to deliver custom solutions backed by our global support network.

Contact our team for help with your application.

“This customer needed a custom system with a lot of flexibility. We worked with them for months to design it, and gave them many quotes to help refine the design. I’m very proud of the work our team did…and also proud of the fact that originally, this customer wanted to use another supplier! They chose Graco because we could do it better and more economically.”

-Mike Bozzelli

Related Articles

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite™, the longest-lasting pump construction for abrasive material dispense.

Foam Encapsulation of Cylindrical Cells

Careful attention to thermal management and foam encapsulation are important to manufacturing high-performance battery modules that remain safe in any circumstance.

Why Electric Motors Improve Quality and Precision of Dispense for 1k Metering

Electric motors have the capability to drive the pump lower more intelligently and therefore dispense an accurate bead without the need for an intermediate metering device.