Reduce Downtime Caused by Adhesive Charring

Adhesive char causes the most downtime and safety incidents at many end-of-line packaging operations. Gain the insight needed to keep char from killing productivity on your case and carton sealing line.

What is Adhesive Char or Charring?

When adhesive properties are altered through thermal and oxidative degradation, the thermoplastic nature of the adhesive is lost, leading to overheating or "charring" of the adhesive.

Adhesive char is the single major cause of hot melt equipment failure and downtime for end-of-line packaging and case and carton sealing applications.

Overall downtime from adhesive char can easily cost $5,000 to $15,000 per hour/per line, due to:

- unplanned downtime when char plugs hot melt hoses and dispense nozzles

- planned downtime to scrape char buildup from the inside of a tank

How Does Char Cause Unplanned Downtime?

Traditional hot melt systems use heated tanks that maintain large volumes of molten adhesive for hours or days at a time. During the long heat soaks and varying fill levels, adhesive charring produces:

- hard clumps that cannot flow through the system, plugging hot melt hoses and dispense nozzles

- buildup inside of hot melt hoses that makes it almost impossible to maintain consistent glue viscosity throughout the entire system

Both cause unplanned downtime that negatively affects the productivity of the manufacturing process. To help minimize downtime, packaging line operators often keep a surplus of replacement nozzles and hoses on hand. But they still need to stop production whenever a hose or nozzle needs to be un-plugged or replaced.

Adhesive char can also get into the system’s pump, leading to premature failure of fluid seals in pumps and guns.

Char-related Costs Impact Profitability

Depending on the problem and the production process, adhesive charring can significantly impact profitability. These examples of hard costs from char-related issues come in addition to unplanned downtime:

- $800 to $1,500 to replace a hot melt hose at $100 per foot

- $1,500 to $5,000 for pump replacement and the rebuild process

- $7,000-$17,000 for additional tank-based melters

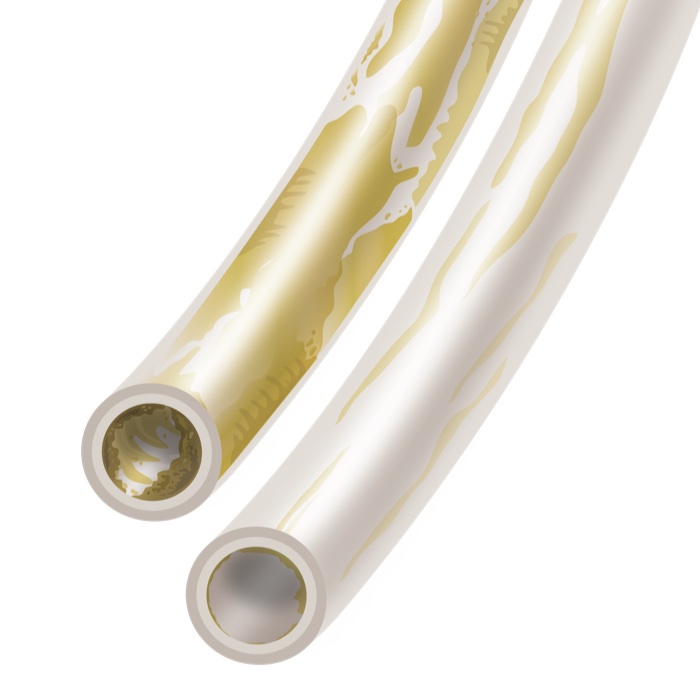

Similar to plaque in a hardened artery, layers of char build up inside a hot melt hose. Char buildup makes it difficult to effectively maintain consistent glue viscosity. As a result, hoses must be replaced frequently.

How Does Adhesive Char Cause Planned Downtime?

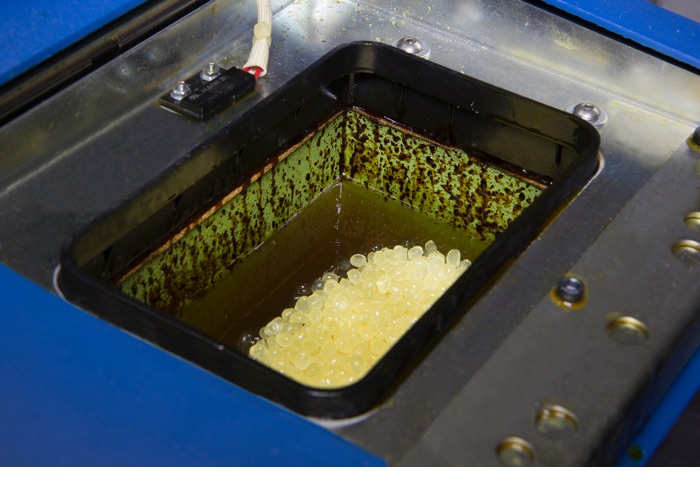

Adhesive char must be scraped off the walls of this hot melt tank.

To avoid excessive char buildup, heated tank systems require routine cleaning and maintenance. These cleanouts can be labor intensive and time consuming, further affecting uptime and productivity.

Manufacturers may have to take tanks offline to completely scrape adhesive char buildup from the inside of a tank. To help minimize planned downtime, some factories have extra hot melters available to keep lines running.

The Cost of Cleaning Hot Melt Tanks

Routine tank scrapes can take at least half a day to accomplish, costing $1,000 to $1,500 in labor and overhead.

Companies not equipped to do the tank scrape in-house may have to send the tank out to have the char removed. This means additional refurbishing and shipping costs, plus more lost uptime.

Once adhesive char is cleaned out, it takes at least 45 minutes for a tank-based system to reach operating temperature. To avoid wasting uptime during normal production, operators often leave hot melt tank systems on, even when a plant is shut down. Unfortunately, this wastes energy and further reduces profitability.

Tank-Free™ Hot Melt Solution Eliminates Adhesive Char

Tank-FreeTM hot melt technology uses specially designed melting chambers. These melters run much more efficiently than traditional tank-based systems, achieving operating temperature in 10 minutes or less. Less time at temperature results in less adhesive char.

With a minimal melted volume, hot adhesive is dispensed quickly and replenished with a fresh supply. This first-in-first-out process leaves no chance for char to develop. Essentially eliminating adhesive char leads to:

- Less material waste

- Fewer nozzle plugs

- Less overall system maintenance

- Longer fluid seal life

- Less production line downtime

Start-up times are at least 45 minutes with traditional hot melt tanks. The start-up time for Graco’s Tank-Free™ Hot Melt Solution is 10 minutes or less.

Hot Melt Equipment Should Not Dictate Material Options

To deal with the negative impacts of adhesive char formation in their heated tank systems, some manufacturers avoid certain hot melt materials. Others switch to more expensive, temperature stable adhesives that impact their profit margins.

Since adhesive charring usually is not a problem for manufacturers with a Tank-Free™ Hot Melt Solution, they can choose any hot melt adhesive option. Materials, such as metallocene and EVA (Ethylene Vinyl Acetate), provide increased affordability and help manufacturers increase end-of-line packaging profitability.

Related Articles

Beer Packaging Line Ends Backups and Downtime

Summit Brewing Company's packaging manager shares how “we have almost no downtime” with a new tank-free system.

What Causes Hot Melt Adhesive Char

Overheating, contamination and oxidation. Learn about the three causes of adhesive char and how to avoid them.