QUANTM Poultry Case Study

Poultry Plant puts QUANTM Pump to the Test

Poultry processors face a challenge with fluctuating prices, and as a result, producers are seeking ways to manage input costs and maintain product margins while ensuring control of automated processes. Two ways to reduce operating costs are to install high-efficiency equipment to reduce energy consumption and improve plant up-time by minimizing maintenance and repair. Graco’s new QUANTM electric pump accomplishes both and offers a key strategy to improve production in plants.

Replacing pneumatic pump technologies with an electric QUANTM pump can reduce operating costs by up to 80%, reduce noise levels and improve automation and control in the facility.

Common Industry Solutions

The following pumps can gently handle large particles, using flapper valves to minimize product damage during transfer. While these pump technologies are effective for large particles, they each have some common drawbacks.

Vacuum Style Pumps

Unreliable: Complex controls and wiring prone to frequent breakdowns

Inefficient: High energy consumption

Limited automation: PLC offers basic self-diagnostics, minimal automation

AODD Flapper Pumps

Inefficient: Requires compressed air, leading to high energy costs

Noisy: Creates a loud working environment for plant personnel

1:1 Flap Check Piston Pumps

Inefficient: High compressed air consumption increases costs and environmental impact

Noisy: Compressed air contributes to a noisy work environment

Limited automation: Additional components required to improve control

Save Green with QUANTM Electric Pumps

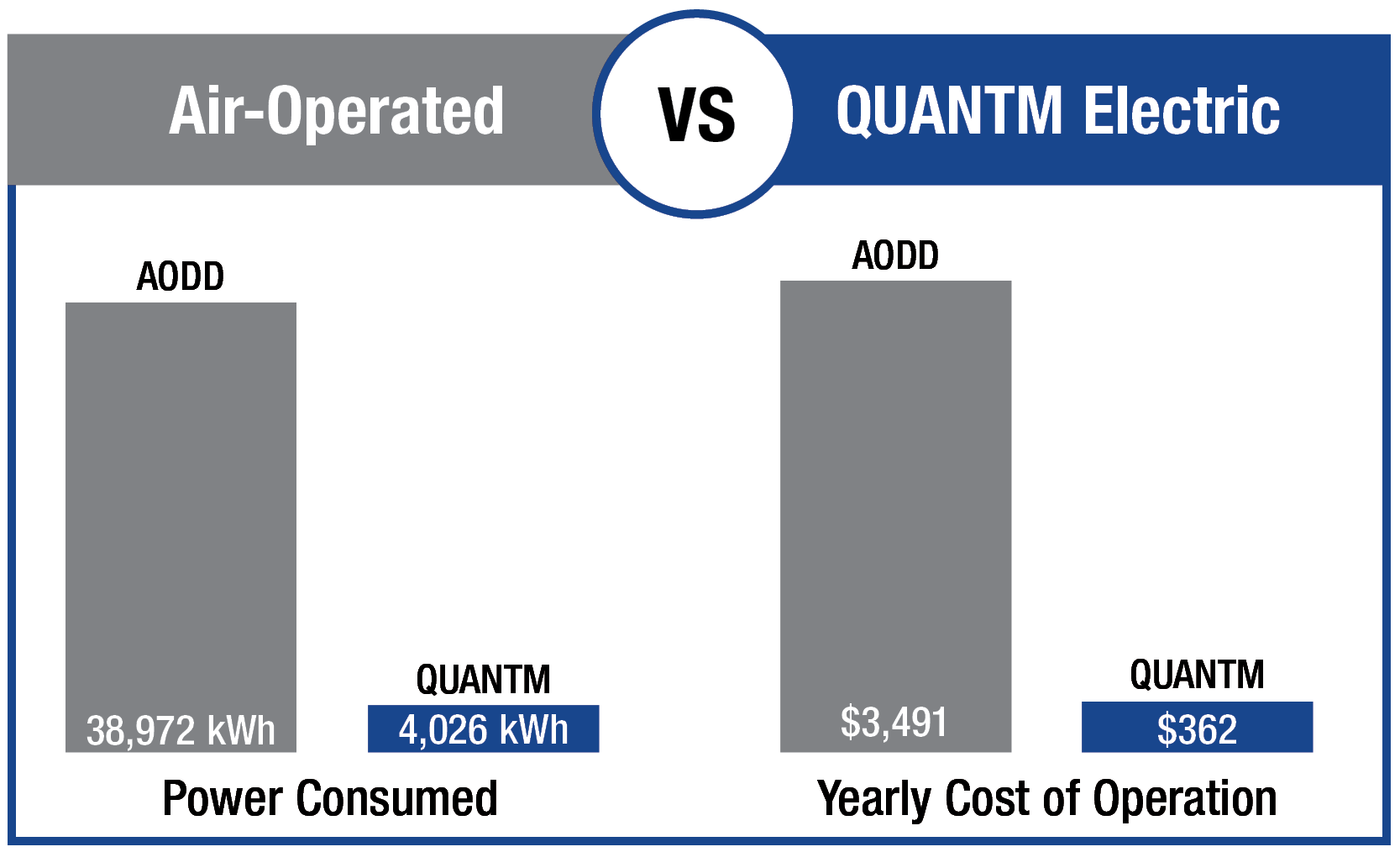

A leading poultry producer embraced QUANTM pumps for their significant energy and cost savings.

See for yourself the estimated savings of a plant running 16 hours a day, 5 days a week compared to a pump powered by compressed air.

QUANTM Pump Put to the Test

The maintenance team at a leading poultry producer sought to improve efficiency and reduce their usage of compressed air. They worked with Graco representatives to install a QUANTM pump in various applications throughout their production process.

Testing Ground

Diverse applications: Blood, fat, livers, gizzards, hearts and neck transfer

Long distances: Pumping over 100 feet to tanks

Previous pumps: VC pumps and AODD flapper valve pump for blood

| Previous Pumps | Why QUANTM? | |

| Noise | Loud and shaking | Quiet operation reduces plant noise pollution |

| Control | Limited control | Increased control for automation and remote operation |

| Maintenance | Frequent breakdowns | No maintenance calls in 10+ months |

| Ease of use | Complex controls | One-touch dial control for easy operation |

| Power source | Compressed air (high expense) | Electric (operational savings) |

| Durability | Unreliable under washdowns | Stands up to daily cleaning |

"The pump just works. We start it up, and it runs without issue. No wiring problems, no control issues, air concerns, nothing."

- Maintenance Lead

Washdown Capabilities

Per USDA requirements, the facility undergoes a nightly washdown procedure during which pumps remain in the room. Cleaning process includes foaming all equipment with specialty chemicals followed by a high-pressure spray wash down with hot water (130° F).

After 10+ months of operation, the QUANTM pump has not experienced any issues or downtime in the facility and is delivering the reliability and efficiencies the plant was looking for.

The QUANTM Benefit

- Up to 80% less energy consumption vs pneumatic

- IP66 washdown rated

- Control flow and pressure at the pump with one-touch control

- I/O for remote operation

- Requires no air

- Quiet operation

Request more info

Related Articles

Different Types of Pumps - Classifications and Applications

There are many different types of industrial pumps, including diaphragm pumps, gear pumps, peristaltic pumps, and more. See an overview of each.

How Does a Diaphragm Pump Work?

Understand the working principle of a diaphragm pump, the different types of diaphragm pumps, and the common uses and applications.

Sustainable paths to profitability

Energy savings and sustainability are becoming profit drivers for companies around the world. Graco can help you build a cost-saving strategy and explore incentive programs to improve efficiency of processing technologies.