The Problem: Difficulty Transferring Corrosive Foods

Mustard and vinegar are two important products people definitely want to buy whether they need mustard for their hot dog or vinegar for their salad dressing. However, there’s a problem when it comes to transferring these materials and that’s the fact they are extremely corrosive and have the capability to quickly degrade stainless steel pumps.

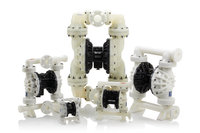

The Solution: FDA Grade Double Diaphragm Pumps

The solution to these challenging material transfer issues is a specific set of purpose-driven configurations of the Husky AODD pump line. When it comes to mustard, air-operated double diaphragm pumps are preferred as this material can damage piston pump seals.

When you select a 1, 1.5 or 2 inch polypropylene Husky Pump, you are getting a food rated fluid section and manifolds.

When coupled with:

- PTFE (standard or overmolded) or Santoprene Diaphragms

- Stainless Steel, Polypropylene, or PTFE Seals and Check Balls

You get a complete pump with FDA compliant materials that can hold up against the corrosive nature of vinegars/acidic ingredients that you are pumping.

Related Articles

Selecting the Right Food and Beverage pump

Four characteristics to consider when selecting a food and beverage pump

2,900 Pounds of Tomato Unloaded in Less Than 10 Minutes

You are standing next to another 300 gallon tote of tomato paste. It is going to take 2 of your employees all day to unload the material so you can begin cooking. Market demand is going up and orders are starting to fall behind. You have a huge bottleneck. You need a solution.