EV Manufacturer Ahead of Schedule with Innovation and Global Supply Collaboration

Background

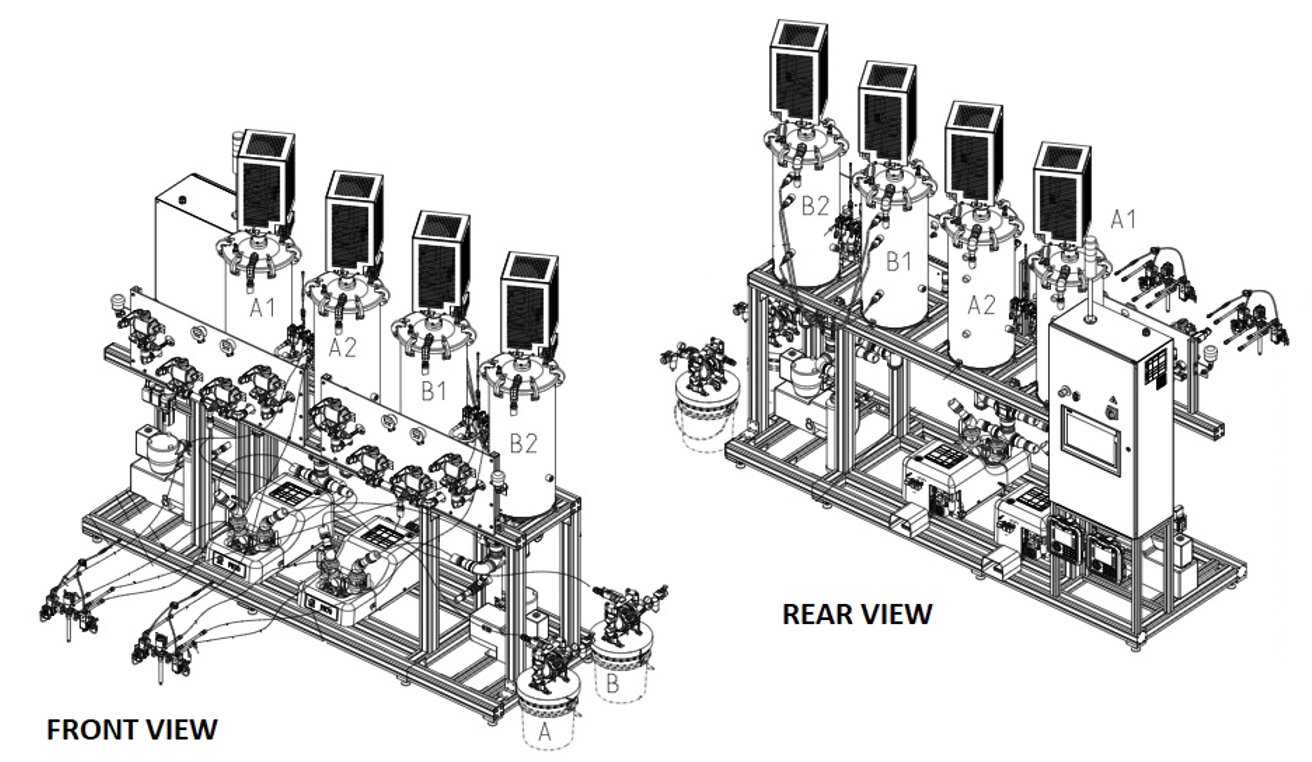

A large electric vehicle manufacturer needed a system to automatically fill and degas the potting material in the electric junction boxes of their EV charging stations. Graco had supplied their previous system, and they came to us for a solution.

The Challenge

To keep pace with changes in the EV production world, the manufacturer needed to revise the design of the system we had originally supplied and required numerous new components—some with long lead times. To solve these issues, we worked with our customer to create new, custom components.

Our Approach

To execute this project and meet the customer's timetable, we needed to quickly design and build a new system that could be integrated into their production lines. Three parts of their auto degas system - the degassing hardware, the recirculation units, and the control panel, required special engineering to get to a solution. Our partnership produced an innovative system that met our customer's production requirements and their timetable.

- Dual PR-70F units on a custom extruded aluminium frame.

- Four 75-liter stainless steel tanks.

- Auto degas valve plates.

- Diaphragm pumps for refill.

- Custom control system

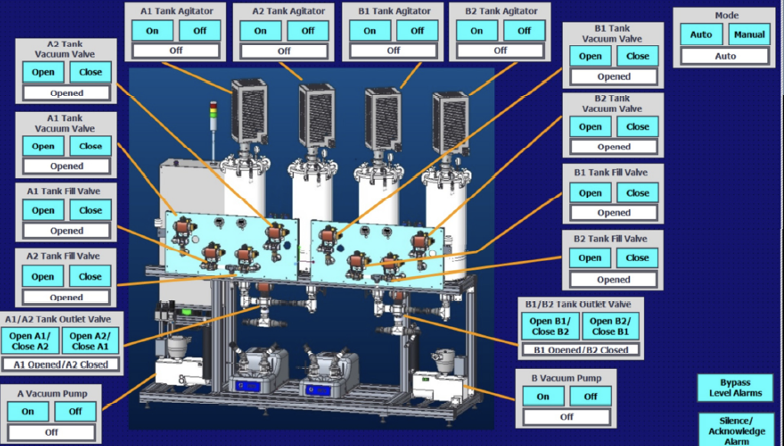

Control System

Our customer specified a Siemens Open PLC (programmable logic controller,) for the control system, which runs on Windows. They also specified a 15-inch HMI (human-machine interface.) The PLC needed to handle 58 inputs and 40 outputs to control the fill, degas, recirculation, and PR-70F functions, as well as the manufacturer’s control interfaces.

HMI Screen

Siemens PLC

Degassing Hardware

Recirculation Units

Degassing Hardware

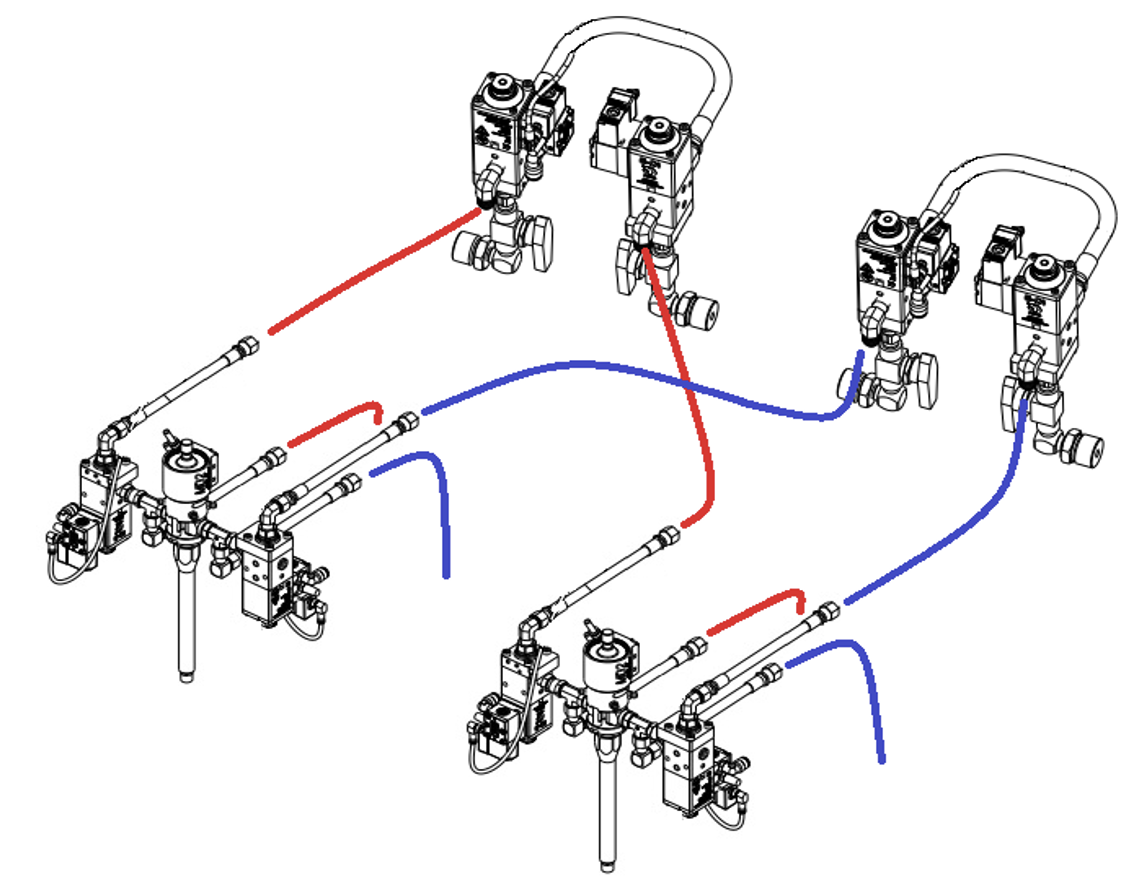

Each component of the potting material requires two tanks, so while one tank is being used by the PR-70F units, the other can be loaded and degassed. Automatic fill/degas ball valves load the potting material, then pull a vacuum and isolate the tank from the PR-70F while degassing. These valves are mounted on a large plate, and the tank outlet valves are under the tanks. All valves have proximity sensors to ensure they are in the correct position during the sequence.

Recirculation Units

Both components of the potting material are filled and must be recirculated to keep these fillers from settling out.

Outcome

Graco’s engineering team partnered with our customer to create a custom Auto Degas solution for their system. We took advantage of our worldwide network to work around long lead times for some of the key components needed for this project, which allowed us to deliver this system in only 22 weeks, two weeks ahead of schedule.

CONTACT EV BATTERY APPLICATION EXPERTS

We understand the complexity of electric vehicle (EV) battery designs, and how material application affects their manufacturability and ability to mitigate thermal runaway events. We look forward to collaborating with you.

"We had to jump through a lot of hoops to make this happen! The engineering team designed the control panel for the degassing hardware from scratch, and we fought some difficult supply chain issues. This project was really a triumph of cooperation with our partners across the world."

- Mike Bozzelli

Related Articles

Foam Encapsulation of Cylindrical Cells

Careful attention to thermal management and foam encapsulation are important to manufacturing high-performance battery modules that remain safe in any circumstance.

Thermal Management for EV Battery and Electronics Manufacturing

Whether it’s assembling electric vehicle (EV) batteries and electronic products, or miniaturizing printed circuit boards (PCBs), thermal management remains crucial to longevity, efficiency and safety.

Battery Pack Seal - EV Battery

A quality seal is critical for the performance and longevity of EV batteries and for protecting integral components from water intrusion and other harsh environmental conditions.