Pressure Vessels & Reactors

High Pressure Equipment (HiP) designs pressure vessels and reactors for both bench-scale and pilot plant applications. Experienced in the fabrication of high pressure reactors and vessels, HiP provides the capability to utilize exotic pressure vessel materials, in addition to manufacturing vessels that meet ASME code requirements.

From elevated pressure testing to hydrotesting, pressure vessels are widely used in a number of applications across a variety of industries. Graco High Pressure Equipment boasts extensive experience in the development of pressure and reactor vessels for the following markets:

- Oil & Gas

- Aerospace

- Universities

- Industrial

- Automotive

- General Research

Experts in high pressure vessel design & manufacturing

Standard & Non-Standard Pressure Vessel Materials

While our common pressure vessel designs are offered in standard materials (316SS, 304SS and 4340 alloy steel), HiP fabricates custom reactor and pressure vessels with exotic materials, including Hastelloy C276, Inconel 625, Inconel 825 and Titanium Grade 5. Other less common pressure vessel application materials can be used upon request.

Designed for ASME Pressure Vessel Codes

Many applications for reactors and pressure vessels demand ASME approval and require designs that meet ASME code standards. HiP produces a variety of pressure vessels and reactors that comply with BPVC code and still meet specific design targets required for unique applications across a variety of industries.

Expert Support and Guidance

Knowledgeable and responsive, the expert team at Graco High Pressure Equipment understands the pressure vessel design process and works cooperatively with you to provide a solution that meets your exact needs. Offering best-in-class service, HiP professionals deliver personalized support that enables your success.

About Graco High Pressure Equipment

Founded in 1954, Graco High Pressure Equipment Company (HiP) provides quality components and systems for elevated pressure applications. HiP works alongside customers to provide A+ technical/engineering support to ensure solutions are tailored to meet custom application requirements and product delivery timelines.

Browse Pressure Vessels & Reactors

Filter results

Standard Material

Maximum Temperature (°F)

Maximum Working Pressure (psi)

Maximum Standard Capacity

Minimum Standard Capacity

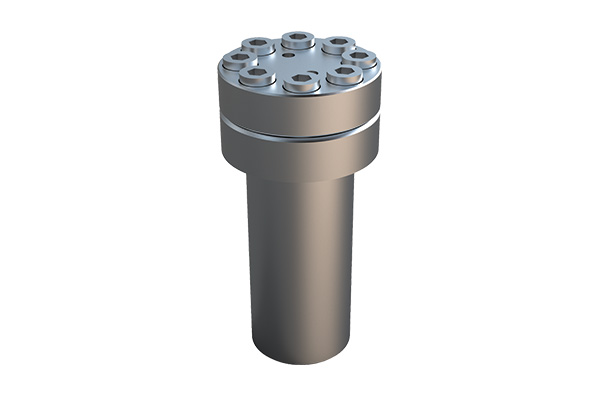

Series BC reactors are the standard of the industry for applications involving moderate pressure ranges. Standard O-rings may be used in place of the metal gasket for lower temperatures.

Series CL reactors feature a quick opening cover design which requires only one-eighth of a turn rotation for sealing. These are high- pressure vessels ideal for operations requiring repetitive opening/closing.

Series GC reactors are designed for studying high temperature and pressure reactions. The pressure vessels utilize thrust bolts and a thrust ring to ensure positive seating of the gasket.

Series MS are fixed bed tubular reactors designed for a variety of applications such as small volume component testing and miniature scale reaction tests.

Series OC reactors are economical and reactors ideal for low-temperature gas or liquid service. A simple closure design allows for easy assembly/disassembly and reliable operation.

Designed for extremely high pressure/low temperature operation, Series R reactors feature a threaded closure for easy assembly and disassembly.

This line of economical and versatile tubular reactors satisfies many moderate-pressure applications. Accumulators can be customized with a variety of options including piston separators.