Corrugated carton Manufacturing - A sticky business

Without pumps the corrugated cardboard production industry would grind to a halt. Pumps mix, transfer and circulate your glue. Air-operated pumps are the logical choice but what if there would be a greener and more cost-efficient solution. Find out why leading companies in your field already switched from air to electric. And how our glue pumps reduce downtime, simplify maintenance and make your processes greener.

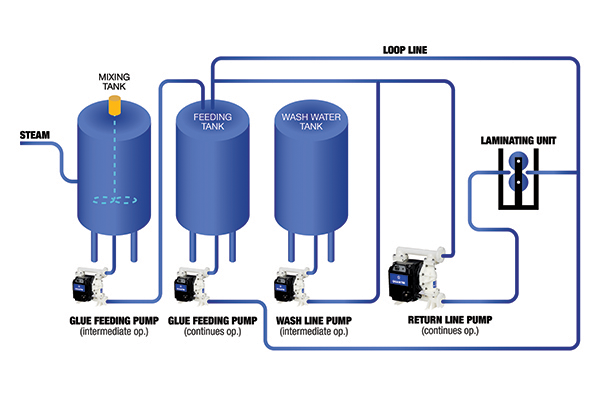

Our glue pumps got your entire glue circulation covered

Whether you are looking for an electric pump for your glue transfer or circulation: we got you covered. We work closely together with glue manufacturers to ensure the best possible handling.

Want to test out our electric pumps with your specific adhesive? We are more than happy to set up a test.

Electric beats air every time

Sustainability – mitigate the effects of climate change by producing up to 5 times less greenhouse gas emissions

Reduce downtime – easier cleaning, fewer parts and faster repair

Lower operation costs – no need to purchase or maintain an air compressor

Reduce energy costs by up to 80%

Stall under pressure – No additional accessories needed to prevent blockage.

Which electric pump suits you best?

Graco offers an extensive range of electric pumps that ensure the quality of your products and cut back on operating costs.

QUANTM

Our new state-of-the-art electric pump. A true game-changer with a revolutionary electric motor design.

- 8x more continuous torque at low speeds

- ROI of just one year

- Plug-and-play installation

Bronze Award Winner for Best Innovation at the FEFCO Conference 2023

Save on energy costs on carton manufacturing and cut back your carbon emissions with QUANTM

A leading UK corrugated cardboard producer replaced 65 2” air-driven pumps with the QUANTM electric pump for his glue circulation lines in 12 factories throughout the country. The impact on energy costs and carbon reduction is huge. The energy consumption dropped from 2,37milj to 535000 kW/year. Combined with the elimination of the cost of compressed air and air compressor maintenance, and the low maintenance costs on the pumps, their investment was paid back in less than 6 months.

And not to forget that by switching to QUANTM, they reduced their carbon emissions by 80%

More than 90 years of experience

At Graco, we strive to find a pumping solution that fits your process. We tailor our equipment to your specific needs.

We are the industry’s highest-quality manufacturer of fluid handling products, cutting across several markets. Founded in 1926, we are now a global company with 3,500 employees, with more than 75 years of experience in the processing and manufacturing industry.

Knowledge hub

More in-depth examples of how you can cut back on your operating costs? Want more advice on choosing the right electric pump for your company?

Why choose an electric-driven double-diaphragm glue pump for corrugated cardboard manufacturing?

An electric-operated double-diaphragm pump definitely has “clear” advantages over its air-operated equivalent. Let’s have a closer look.

Glue pump features for efficient corrugated cardboard manufacturing

Learn more about how pumps are used for glue transfer and circulation in the corrugated cardboard manufacturing industry. Dig into key pump and material features that are important to consider when transferring or circulating glue.

Corrugated Carton Case Study

A UK manufacturer has replaced nearly 115 AODD pumps with QUANTM for starch glue circulation lines. The impact on their energy costs and carbon reduction is substantial.

Common problems with glue pumps and how to fix them

The higher the viscosity, the more difficult it becomes to prime the pump. One solution is to apply light heat to the pump. This lowers the viscosity of the glue, facilitating priming and pumping.