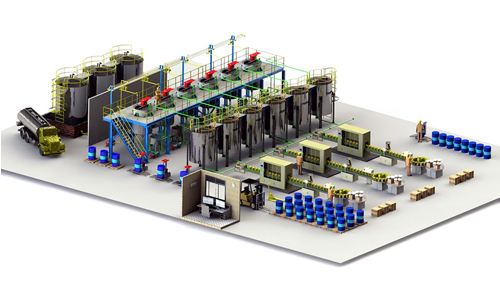

Chemical Blending

In chemical blending processes, sustainability and safety are critical priorities that influence each step. From the initial unloading of raw materials from tanker trucks or rail cars to the precise blending of chemicals, and bulk transfers into different containers, Graco’s fluid transfer solutions lead the way in ensuring both efficiency and safety. Graco's cutting-edge technologies not only optimize operations, but also help minimize waste and reduce environmental impact, meeting the industry's growing need for sustainable practices.

Chemical Transfer

Whether transferring chemicals or managing waste, Graco fluid transfer pumps offer solutions that enhance operational safety and adhere to regulatory guidance. As the industry faces ongoing challenges in regulatory complexity and the need for sustainable innovation increases, Graco remains committed to delivering solutions that empower businesses to achieve their environmental goals while maintaining top-tier safety standards throughout their operations.

ELECTRIC BEATS AIR EVERY TIME

SUSTAINABILITY

Mitigate the effects of climate change by using significantly less energy, reducing greenhouse gas emissions and eliminating the reliance on air compressors.

WORKER SAFETY

Effective noise reduction, combined with no muffler, built-in leak detector and seal-less design prevent hazardous leaks and eliminates the risk of harmful material being airborne.

NEXT-LEVEL PLANT PRODUCTIVITY

Boost automation by linking QUANTM to your plant software for pump monitoring and enhanced controllability.

COST EFFICIENCY

Reduces maintenance costs with extended pump life and protection from pressure-related damage.

ADVANCED METERING

Offers precise flow control, adjustable flow rates, and remote operation for more accurate dosing and mixing.

Why choose an electric-driven double-diaphragm pump for chemical blending?

QUANTM isn’t just another chemical pump: it’s a game-changer. QUANTM features a revolutionary electric motor design that significantly improves pump efficiency. This design reduces noise and eliminates the muffler to contain material inside the pump, keeping your plant personnel safe.

Knowledge hub

The role of pump technology in LOC prevention in the chemical industry

Preventing loss of containment (LOC) incidents is paramount for ensuring the well-being of employees and maintaining a safe work environment. This article explores the causes of these types of incidents and proposes preventive measures, with a particular focus on the role of pump technology in conta...

Chemical transfer pump QUANTM: Selecting the right pump

Safer, quieter, more advanced capabilities, with reduced energy usage and CO2-emissions: in a nutshell the main advantages the QUANTM electric pumps have over centrifugal pumps and air-operated double diaphragm pumps. But where in your processes is the added value most significant and what pump conf...

Chemical pumps: Why go electric?

Chemical companies typically use centrifugal or air-driven pumps for various processes. However, Graco's QUANTM electric double diaphragm pumps (EODDs) offer several advantages for chemical applications. Here are six reasons to consider Graco's QUANTM pumps over other technologies.

Case study: Double Diaphragm Pumps in Chemical Application

A chemical manufacturer transitioning to a newly purchased facility sought to reduce their reliance on compressed air. As the facility was being completely renovated into a new manufacturing plant, they had the opportunity to evaluate and install a variety of pumping options and technologies. Previo...