Glue Pump Features for Efficient Corrugated Cardboard Manufacturing

The role of glue pumps in corrugated cardboard manufacturing

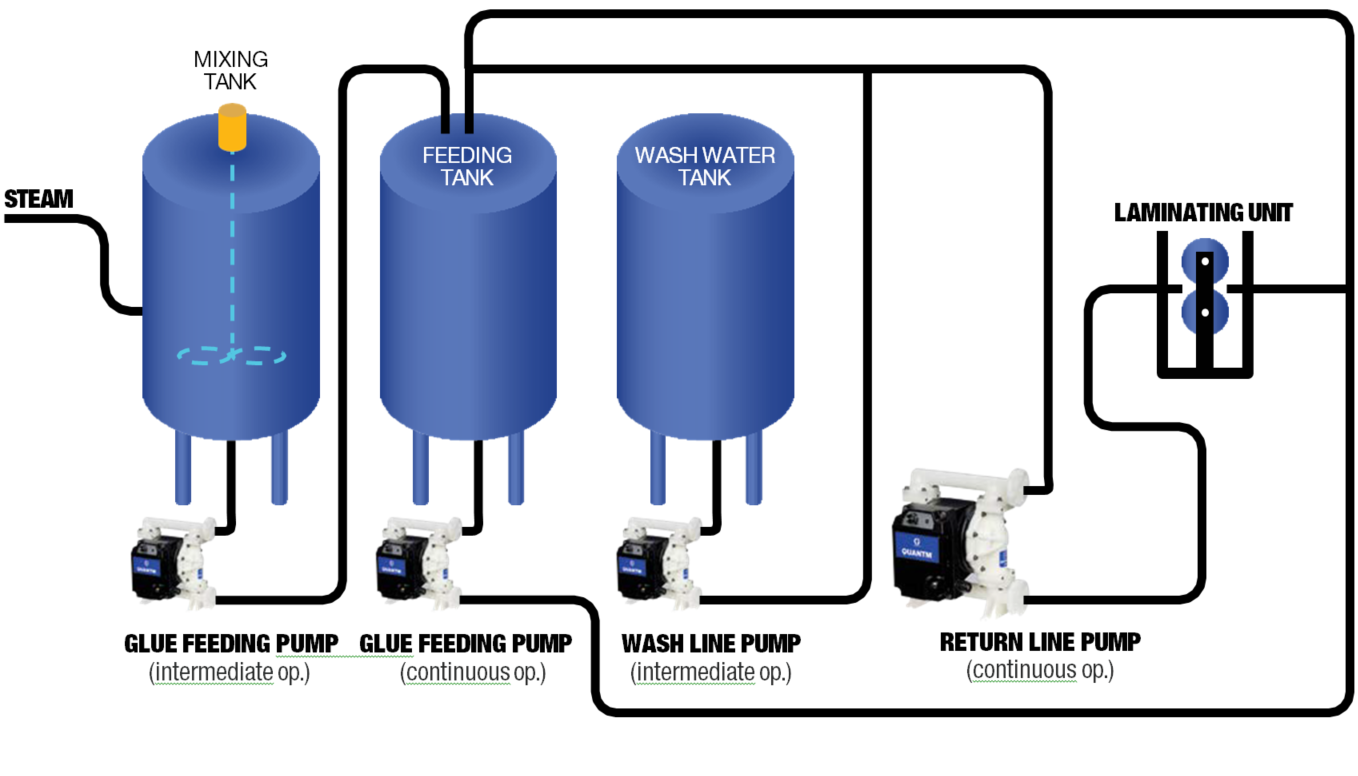

Glue Transfer

Without glue, the corrugated cardboard industry would grind to a halt. Pumps are needed to transfer the glue throughout the production process.

Pumps are a necessity in the carboard manufacturing process as they transfer the glue to the single facer and the glue machine.

The glue itself is prepared in the glue kitchen where it is collected in the buffer tank. From there, a pump is needed to move the glue from the main storage bucket into separate storage buckets beside the single or double facer glue pans.

The glue roll picks up the glue and transfers it to the medium tips, while the metering roll keeps constant glue thickness on the roll in order to deposit a constant volume of glue on each tip.

Glue: a sticky business

- Abrasiveness: Some glue contains ingredients with small particles. These particles wear against the pump's internal components causing failure.

- Corrosiveness: A chemical reaction can occur between certain glues and the pump's materials of construction and cause corrosion inside the pump.

- Shear Sensitivity: Many glues are shear-sensitive. Meaning, the product may be adversely changed while being pumped due to the shearing nature of the pump's operation. This can affect the performance of the glue.

- Viscosity: Viscosity is a major factor in choosing the right pump for a glue application. Glues can have a wide range of viscosities. Highly viscous liquids affect pump performance and output.

- Temperature: Some pumping technologies can heat up glue during operation; electric-operated double-diaphragm pumps do not have this effect. In general, glue temperature should not exceed 43°C otherwise the glue could turn into a gel.

- Flow: Minimum and maximum flow rates must be understood in order to efficiently manage glue transfer and application.

Glue Circulation

To prevent the glue from settling in the glue pans, it’s constantly circulated to and from the buffer tank. Here, another pump is needed to transfer the glue from the glue pans back into the buffer tank.

Any remaining glue flows into a tray under the machine. A third pump is installed here to move this remaining glue in the tray to a storage bucket. From there it can be recycled and reused.

After shutdown, all glue in the corrugated line unit is pumped into the main storage tank for use the next working day.

Conclusion: For every corrugated cardboard manufacturing machine in operation, at least three pumps are required.

Glue isn't the easiest material to pump. However, you can pump it efficiently as long as you understand some basic properties of glue.

Double diaphragm pumps: the preferred choice

Glue dries and hardens inside mechanical seals of, for example gear pumps, which make the latter vulnerable to breakdown, leading to costly production downtime.

Double-diaphragm pumps do not have mechanical seals, can stall under pressure and can handle solid particles. They come in configurations that can be adapted to the required abrasion resistance and soda concentration, making them very reliable in glue circulation applications. They are also ideal for pump high-viscosity fluids. Last but not least, price of spare parts is low.

QUANTM: A revolutionary new solution for glue transfer and circulation

QUANTM electric double diaphragm pumps offer a good solution for glue transfer. This new solution is specifically designed to handle even the most demanding glues with ease.

Here's how QUANTM electric pumps set themselves apart:

- Shear sensitive: Unlike other pumps than can damage delicate glue molecules, QUANTM's gentle pumping action ensures the glue's properties remain intact, guaranteeing optimal performance.

- Viscosity? No problem: From thin to thick, QUANTM pumps can handle a wide range of viscosities effortlessly. They even adapt to changing viscosities, maintaining consistent flow regardless of back pressure.

- Cool under pressure: Unlike pumps that heat up the glue, QUANTM pumps integrate temperature sensors into the pump's electronic controls, helping to prevent the glue from turning into gel.

- Stalls for safety: Worried about clogged lines or closed valves? QUANTM pumps can stall under pressurem preventing pump damage and minimizing downtime.

- Built to last: Say goodbye to expensive wear parts and leaks! With no mechanical seals, QUANTM pumps require less maintenance and have fewer breakdowns, even with abrasive glues.

- Energy savings: Go green and save green! The energy-efficient operation reduces energy consumption by up to 80% compared to pneumatic alternatives.

- Quiet operation: By eliminating compressed air from the pumping process, QUANTM pumps deliver significant noise reduction, improving worker health and safety.

- Precise control: The integrated electric controls allow users to adjust speed at the pump using the one-touch dial control. Alternatively, users have the option to connect to the I/O port to enable remote operation and monitoring.

- Rock-solid reliability: Count on QUANTM pumps for 24/7 operation. Its robust construction handles even the most challenging glues with ease.

With QUANTM pumps, glue transfer doesn't have to be a sticky situation. Experience the revolution in efficient, reliable and gentle glue handling.

Interested in going electric?

- Get in touch with our experts

For more information about glue applications and the pumps being used in those applications, fill in the contact form and one of our experts will contact you shortly.

- Calculate your savings

In three easy questions, calculate how much you could save by converting your

facility to Graco electric double diaphragm pumps

Related Articles

Common problems with glue pumps and how to fix them

The higher the viscosity, the more difficult it becomes to prime the pump. One solution is to apply light heat to the pump. This lowers the viscosity of the glue, facilitating priming and pumping.

Why choose an electric-driven double-diaphragm glue pump for corrugated cardboard manufacturing?

An electric-operated double-diaphragm pump definitely has “clear” advantages over its air-operated equivalent. Let’s have a closer look.

Corrugated Carton Case Study

A UK manufacturer has replaced nearly 115 AODD pumps with QUANTM for starch glue circulation lines. The impact on their energy costs and carbon reduction is substantial.