Battery Pack sealing - EV battery

Performance and longevity of EV batteries

Achieving a quality EV battery seal is critical for the performance and longevity of EV batteries and for protecting integral components from water intrusion and other harsh environmental conditions.

Industry standards

EV batteries are subject to increasingly stringent performance and safety standards. Increasing the significance of a reliable and repeatable battery pack seal is critical to the performance, safety, and longevity of the pack. The EV battery seal must meet design and regulatory requirements for enclosure standards, such as IP68, which means that the seal will protect against water intrusion, corrosion, and outside contaminants. The pack must also meet design and regulatory safety standards to enhance vehicle safety and mitigate the risk of thermal propagation/runaway.

Application

In battery pack sealing applications, a bead of material is robotically applied around the perimeter of the casing assembly using cure-in-place (CIP) gasketing or form-in-place (FIP) gasketing methods. CIPGs are dispensed and allowed to cure before assembly, creating a compression gasket in the pack seal joint. Alternatively, FIPGs are dispensed, assembled immediately, and allowed to cure over time. Both gasketing methods provide improved cycle times and have better overall performance compared to traditional pre-formed gaskets.

Materials

To meet the life cycle demands, materials continue to evolve for improved performance, compression, and serviceability. Common material compounds include one or two-component silicones, polyurethane, and butyls.

Challenges

The challenge in a material application is maintaining proper control over dispensing parameters to ensure the bead dimensions and uniformity consistent throughout the dispense. A void or variation in the size of the bead can compromise the battery pack sealing performance. In an FIP gasket, the precision of the bead volume is critical to ensure a complete seal without over-application. In a CIP gasket, the dispensed material becomes a compression gasket. Thus uniform bead dimensions and proper knit line techniques are critical to successful sealing.

A quality EV battery seal

Bead placement, the correct volume of material, flow rate, and in the case of two-component materials, proper mix ratios are the most important factors in ensuring a quality bead. To ensure a durable and reliable seal for EV battery, the application must be clean, precise, and repeatable.

Process development

We take a design-led approach in determining the ideal dispensing solution. Through our development labs, application expertise, and material supplier partnerships, we can test and determine process parameters to deliver a solution that meets your application and production requirements.

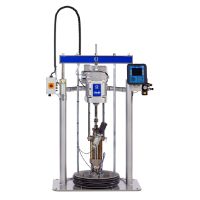

Graco understands the challenges of battery pack sealing applications and has developed system solutions to ensure a reliable seal. Our portfolio of dispense equipment can solve the most common material application challenges in battery design and construction. From industry-proven pumps to custom meter, mix, and dispense systems, we deliver dispensing solutions for reliable and consistent bead application.

Contact an expert

Video: Battery pack seal Dispense

Related Articles

Slurry Dispense for Electrode Coating

Growing demand for EV battery manufacturing requires advanced solutions – and slot die slurry dispense application is no different.

Pressure-sensitive adhesives in EV batteries

EV battery designers and manufacturers recognise how PSAs bring good adhesion and flexibility to cell-to-pack and pouch-cell lamination. Move those applications into production with five questions about hot melt equipment.

Foam encapsulation solution fast-tracks new EV battery production

An EV battery manufacturer had to determine the best foam encapsulation process for a new cell module design. Quick collaboration with Graco put it into production by a critical deadline.