Large EV Manufacturer Increases Flexibility in Production Process with Customised System

Customised system adds flexibility to electric vehicle (EV) battery production process.

Background

A large electric vehicle manufacturer needed a more versatile battery encapsulation system. They aimed to change their process to utilise variable ratio meter-mix dispense equipment.

The Challenge

The manufacturer sought our assistance in designing the system they needed, and they were on a very tight schedule. The development process was demanding, because there was a lack of clarity about some components until late in the timeline. Indeed, some of the key components were designed after development had commenced.

Our Approach

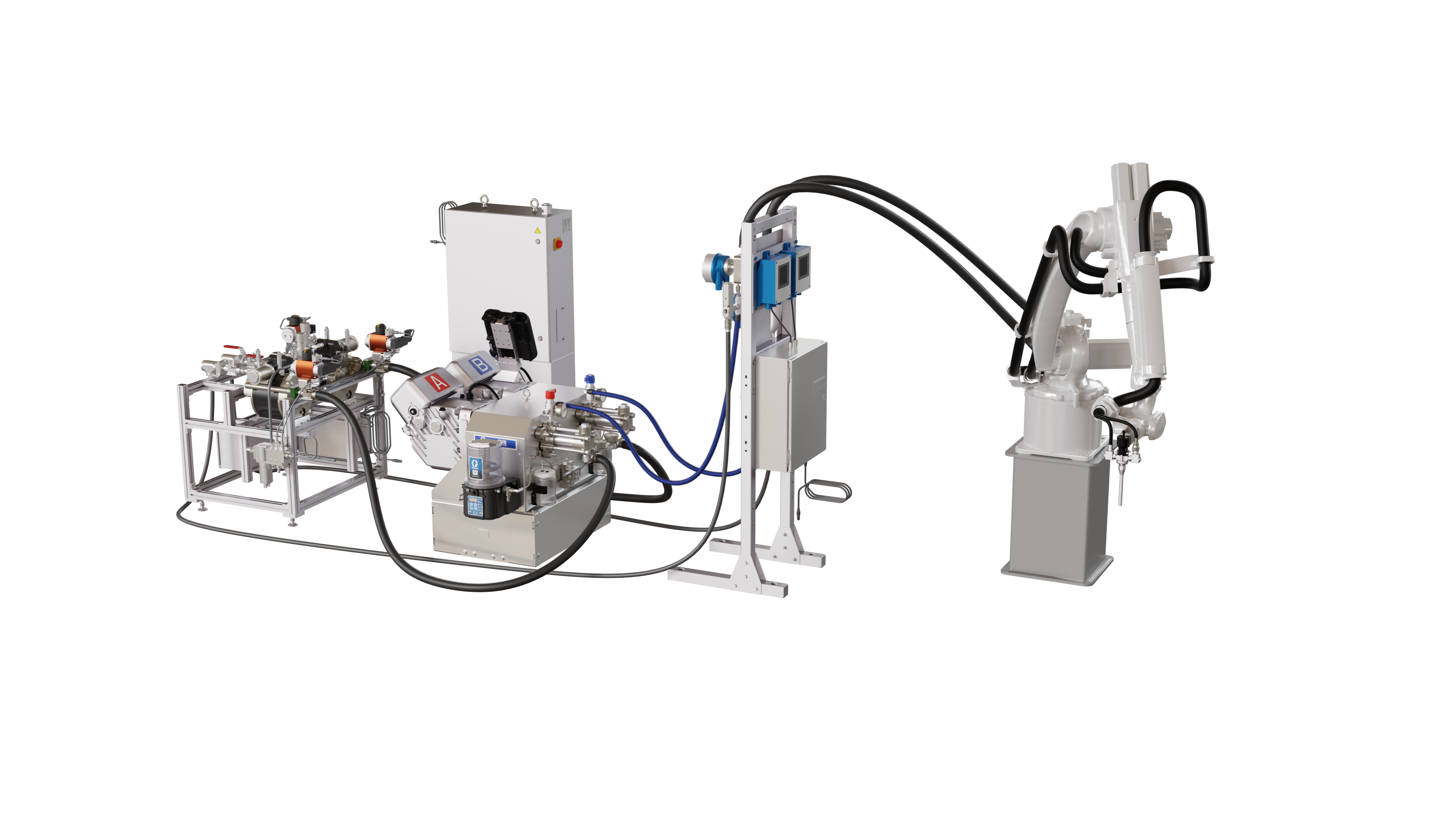

The Graco engineering team collaborated with our customer to create a system tailored to their needs. We proposed an EVR (Electric Variable Ratio) system that enables mixing, metering, and dispensing a range of two-component materials with the same equipment. The result was a customised system that enhanced our customer’s production process flexibility and was delivered ahead of schedule.

Electric Variable Ratio (EVR) Metering System

- 480 volt 3-phase power supply

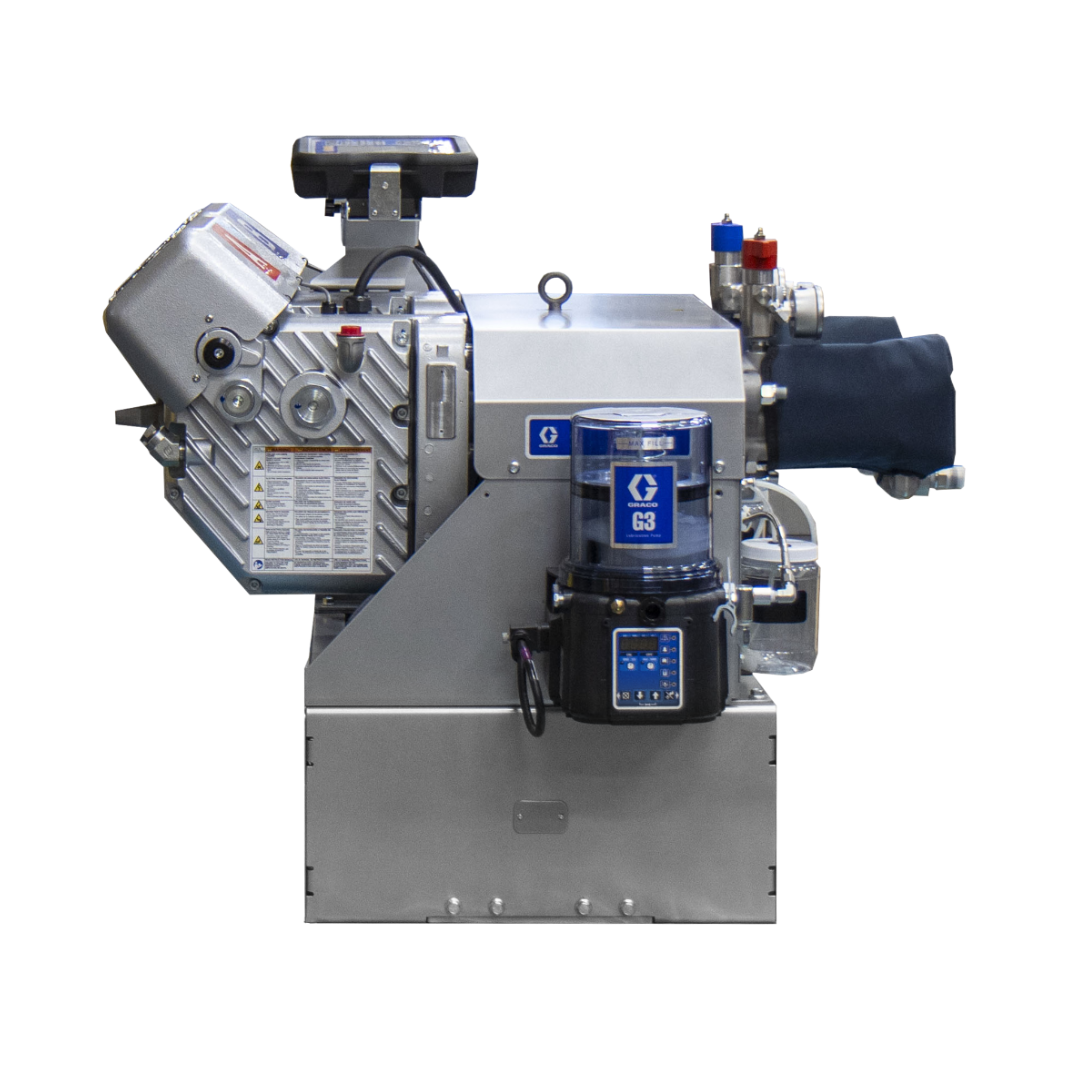

- Graco G3 Electric Grease Pump to Auto Grease Z-Pumps

- Heated Hoses with Integrated Heat Controller

- Mass Flowmeters for ratio monitoring

- Automatic Inlet Ball Valves for Material Inlets from customer bulk supply

- Recirculation for B Side Material

- Entire System Controlled By One ADM

Custom-engineered major components to create a specialised solution:

- Inlet assembly – automated ball valves for A side, B side and recirculation

- Coriolis mass flowmeters for ratio monitoring

- Heat control box

- 480-volt EVR with automated Z-pump greasing

Inlet Assembly

Flowmeters

Heat Control Box

EVR

Outcome

Our manufacturing client required many specialised components within a very tight timeframe. By working together, we developed an integrated system that addressed our customer’s needs, shipping the first unit in only 18 weeks.

CONTACT EV BATTERY EXPERTS

We understand the complexity of electric vehicle (EV) battery designs and how material application influences their manufacturability and ability to mitigate thermal runaway events. We look forward to collaborating with you.

"This customer required a host of specialised components, delivered promptly and our engineering team rose to the challenge, crafting a solution. Despite some components being designed and built post-order, the first unit was shipped just 18 weeks later."

-Mike Bozzelli

Related Articles

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite, the longest-lasting pump construction for abrasive material dispensing.

Foam Encapsulation of Cylindrical Battery Cells

Learn about foam encapsulation and its role in the manufacturing of high-performance battery modules that remain safe under all failure conditions.

Case Study: Li-ion Battery Manufacturing

An EV battery manufacturer had to determine the best foam encapsulation process for a new cell module design. Quick collaboration with Graco put it into production by a critical deadline.