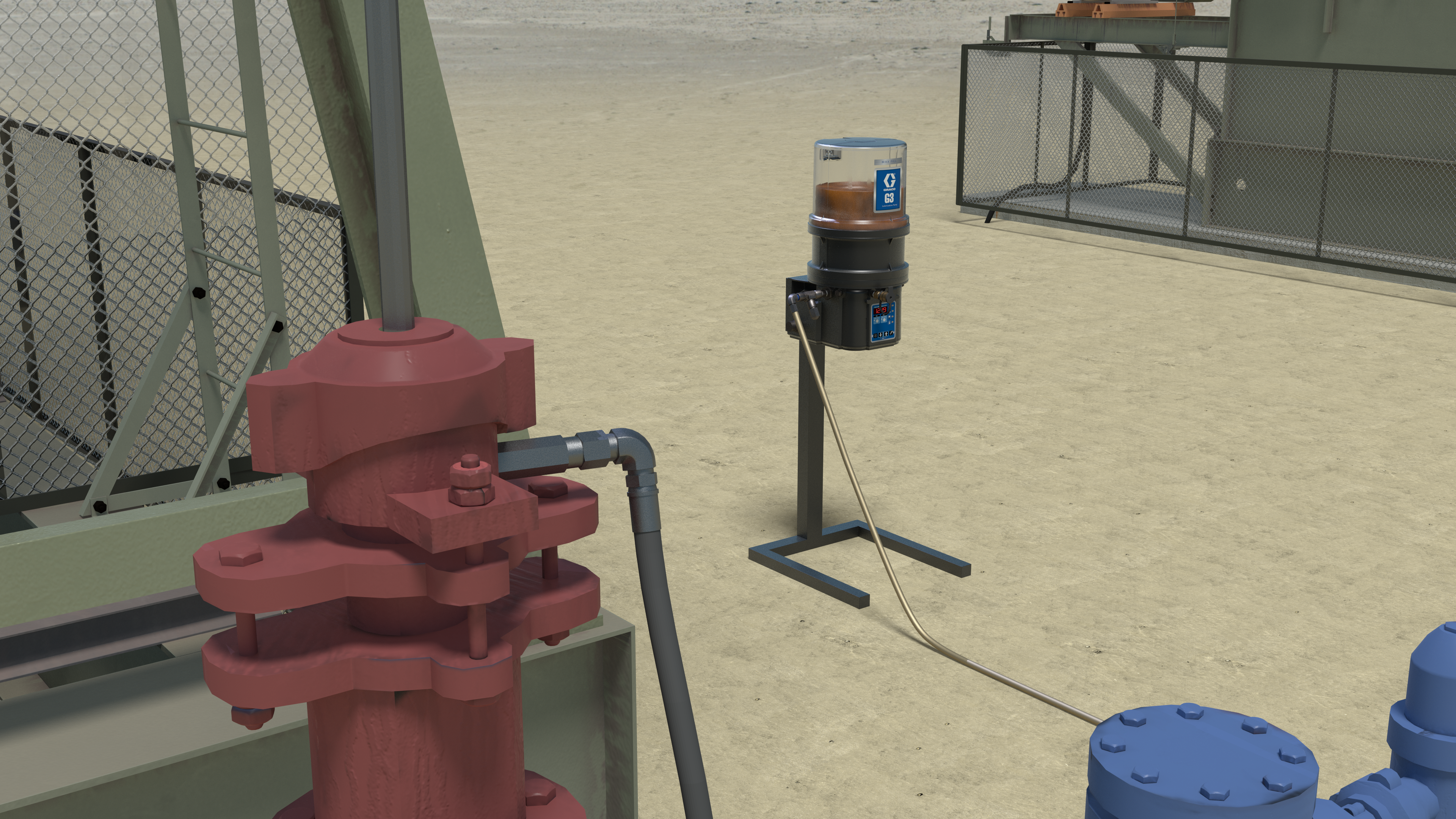

Rod Lift Stuffing Box Lubrication Solutions

EXPERIENCE TOTAL COST OF MAINTENANCE REDUCTION WITH AUTOMATIC LUBRICATION FOR ROD PUMP STUFFING BOXES

*Click a button above for more information.

Sustainability You Can See

Comply with Environmental, Safety and Health (ESH) standards with a solution that keeps the equipment and ground clear of material. Thinking of the material outside your rod pump stuffing box as lost profit, automatic lubrication becomes a smart choice at a glance.

Stuffing box appearance after conventional application of lubricant

Stuffing box appearance after introduction of automatic lubrication

Why Use Automatic Lubrication for Rod Pumping?

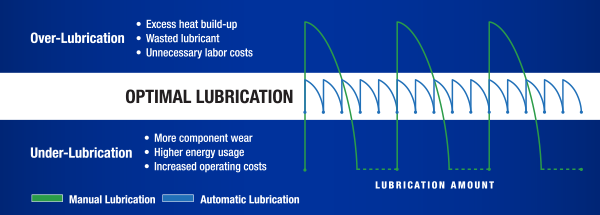

When compared to manual or beam driven lubrication methods, automatic lubrication for rod lift stuffing boxes offers distinct advantages for oil and gas production.

Automatic lubrication ensures that your equipment receives the perfect amount of lubricant precisely when needed, avoiding under-lubrication that can lead to premature wear and over-lubrication that can cause messy and costly spills.

Choosing Automatic Lubrication:

Provides consistent lubrication to minimize wear and maintenenace costs

Saves time and labor by eliminating manual lubrication tasks

Minimizes environmental impact by preventing excessive lubricant usage common with manual or beam actuated methods

Explore G3 Series Pump Options

Built to handle changing temperatures and challenging grease types with ease.

$5,000+*

ESTIMATED YEARLY SAVINGS PER ROD LIFT INSTALLATION

BY REDUCING MAINTENANCE COST & REGULATING LUBRICANT USAGE

*Estimate reflects savings reported by customers in testimonials and feedback

Ready to save? Contact our team for a personalized estimate

Curb the Impact of Polished Rod Friction

The stuffing box is designed to seal around the polished rod, preventing fluids from escaping while allowing the rod to move. However, the constant movement of the polished rod through the stuffing box can lead to friction, potentially wearing down the sealing elements and the rod itself, which might necessitate maintenance or packing replacements to ensure a proper seal and proper operation.

Improper alignment in a sucker rod pumping system, whether due to the bending of the wellbore or misalignment of the system components, increases friction and wear. Overheating due to friction between the polished rod and the stuffing box packings can degrade the packings, reducing their ability to maintain a seal and leading to leaks. This wear can also increase maintenance needs and operational costs, emphasizing the importance of proper lubrication and alignment to mitigate friction and preserve the integrity of the stuffing box.

Addressing rod lift system maintenance proactively is crucial. Even small failures can incur significant costs, far outweighing the investment in regular maintenance. Whether a failure results in minor repairs or full system downtime, the financial and operational benefits of maintaining equipment properly are undeniable.

Thus, investing in automatic lubrication for rod lift systems is not just a matter of operational efficiency—it's a cost-effective strategy to prevent expensive failures.

.png)