Concrete Surface Prep Part 3: Surface Roughness Grade

Adequately Roughened

With the concrete sound and contaminant-free, all that’s left is to adequately roughen the surface, but to what degree? The blasted concrete surface is too rough to be measured by tape and quantified in microns or mils.

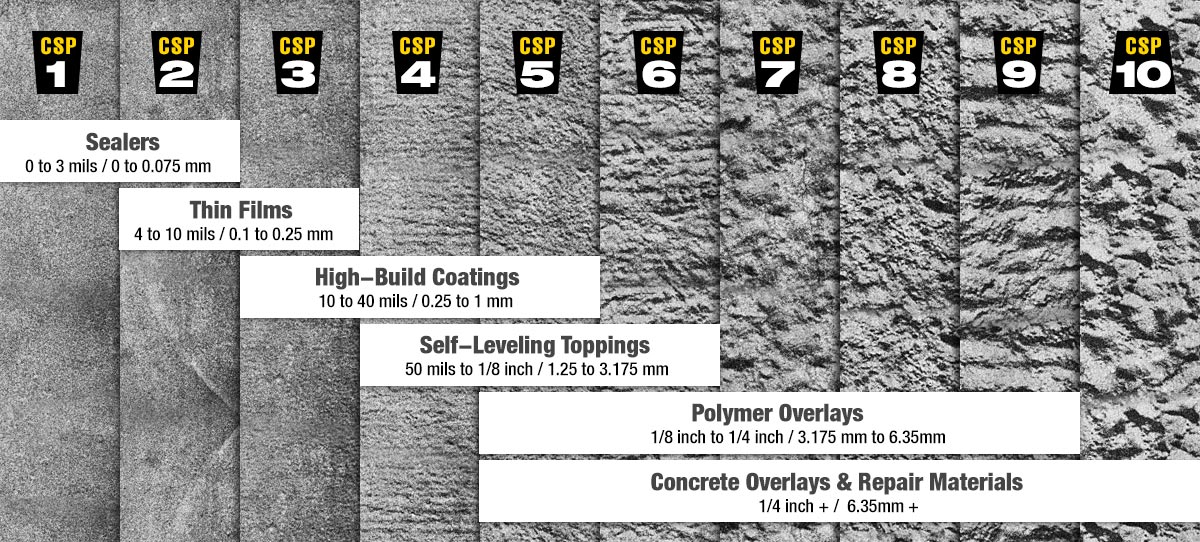

The most effective reference tool for determining concrete surface profiles is the molded rubber comparator chips, available from the International Concrete Repair Institute. These samples replicate ten grades of surface roughness, and are designed for direct visual and tactile comparison to the concrete surface in question.

There is no definitive text description for the ten grades: the comparator is the standard. However, ICRI does tell us how much surface profile is sufficient for various types of coatings and overlays:

ICRI also indicates which methods of surface preparation can be used to render the indicated concrete surface profile.

ICRI also indicates which methods of surface preparation can be used to render the indicated concrete surface profile.

Abrasive blasting is one of the most versatile methods, covering a wide range of surface profiles, from CSP 2 to 7. Unlike many methods listed, abrasive blasting can also be applied to vertical and overhead surfaces. However, it can’t efficiently remove concrete to depths obtainable by high-impact mechanical methods like scabbling – although abrasive blasting does play an important role in remediating microcracking inflicted by these methods. Let’s review the options and watch them in action.

Grinding

Grinding removes laitance, protrusions, surface contaminants and produces a smooth or polished surface, depending on the roughness of the abrading discs.

The discs move at right angles to the surface, and may leave circular patterns or gouges in the surface. Floor grinders are used for horizontal surfaces. Hand-held grinders are used on vertical surfaces.

Micro-cracking Risk: None

Acid Etching

Acid etching dissolves cement and exposes fine aggregates, leaving a sandpaper-like finish. It is used to remove laitance and to delicately roughen a surface in preparation for a sealant, primer or other thin coating. Acid is difficult and dangerous to work with: not only are acid fumes a health hazard, but they can etch any stainless steel or aluminium they come in contact with – such as electrical boxes and piping.

Micro-cracking Risk: None

Needle Scaling

Needle scalers pulverize concrete surfaces by the pounding action of steel rods, driven by pneumatic or hydraulic pulses. Needle scalers are commonly used to remove efflorescence and other brittle encrustations. The impacts produce a cratered surface profile.

Micro-cracking Risk: Low

Abrasive Blasting

Abrasive blasting propels dry or moist abrasive in a stream of compressed air. Upon impact, the abrasive particles penetrate the substrate, dislodging fragments of mortar and fines, producing an overall eroding effect. Abrasive blasting removes surface contaminants, unsound concrete, coatings and adhesive films, and imparts a profiled surface.

In addition, vapour abrasive blasting is recommended for removing laitance, efflorescence and gently abrading delicate surfaces. Both methods may be used on horizontal, vertical, and overhead surfaces and are suitable for both interior and exterior applications.

Micro-cracking Risk: None

Shot-blasting

Shot-blasting propels steel shot against the concrete surface by means of a wheel. The impacts of the shot pulverize concrete and contaminants and roughen the surface. Spent shot is separated from waste products and recycled. Shot-blasting is a preferred method for cleaning and profiling horizontal surfaces and has the same applications as abrasive blasting. In some special situations, robots can shot-blast on horizontal planes.

Micro-cracking Risk: None

Water Jetting

Water jetting removes contaminants and roughens the surface via the impact of jets of high pressure and ultra high pressure water. It has the same applications as abrasive blasting and shot blasting, and can be used on vertical and overhead surfaces. It can produce CSP as low as three and as high as ten, ten being equal to the diameter of the coarse aggregate. In other words, water jetting can dislodge aggregates.

Micro-cracking Risk: None

Scarifying

A scarifier consists of rows of toothed washers assembled on steel rods that are mounted to a rotating steel drum. As the drum spins, the washers strike the surface, fracturing and pulverizing concrete, and producing a striated pattern. Scarifying only works on horizontal surfaces.

Micro-cracking Risk: Moderate

Rotomilling

A rotomiller is a scarifier on steroids, so large that it must be driven, with teeth mounted to the drum instead of washers. The impact of the teeth fracture the concrete into chips and dust, creating striations and deep grooving. A rotomiller can be equipped with small teeth to render a CSP of 6, or large teeth that produce CSP 9. It stops short of CSP 10, because instead of dislodging aggregate, the rotomiller breaks it. A rotomiller can only be used on horizontal surfaces.

Micro-cracking Risk: High

Scabbling

Scabblers feature multiple pointed piston heads, pneumatically-driven, that pound the surface, chipping and crushing it. They produce coarse, irregular surfaces and are often used to demolish low concrete structures.

Micro-cracking Risk: Extreme

Hammering

Jackhammers and chipping hammers break up concrete when the point or chisel head fractures the surface, and enters the fracture, and pounding repeatedly until large fragments of concrete break off. They can be used on horizontal surfaces (jackhammers) or vertical surfaces (chipping hammers).

Micro-cracking Risk: Extreme

Surface Retarding

A surface retarder is a chemical sprayed onto freshly poured concrete to prevents hydration from occurring at the surface. The unreacted cement paste can then be removed by pressure washing or scrubbing, exposing coarse aggregate.

Micro-cracking Risk: None

Key Takeaways

So how do you know when you’ve achieved the right concrete surface profile? The ICRI rubber comparators are the most reliable method, but it still leaves a lot of room for interpretation.

The best practice for obtaining a clearly defined target surface profile is to create a job standard. Working with the other stakeholders, develop a surface profile close to the specified CSP as indicated by the comparator. When everyone agrees on the job standard, that becomes the abrasive blaster’s benchmark.

The ultimate indicator of a properly prepared surface is whether the bond holds, which can be tested by the pull-off method. A steel disk is affixed to the finished surface and the concrete around the perimeter is scored, so that upward force is only acting on the area directly below the disk. Pressure is applied to the disk with an adhesion tester until the disk pulls off. If the sample detaches at the prepared surface plane, then the bond was the weakest point in the system, indicating a surface preparation problem. When the bond holds but the concrete fractures at less than 10% of the expected compressive strength of the concrete, it’s a good indicator that the concrete is still unsound.

Tensile strength vs compressive strength

Compressive strength is the measure of a material’s resistance to being crushed.

Tensile strength is the measure of a material’s resistance to being pulled apart.

The two are related, but not directly proportional. Tensile strength of concrete is approximately 10-15% of the compressive strength.

Recommended Resources

ICRI 310 Concrete Specifying Pack. This includes the specifying guide that outlines the CSP schema, plus the 10 rubber chip comparator. If you plan on blasting concrete, you should own this.

Best Practices for Preparing Concrete Surfaces Prior to Repairs and Overlays. This is an excellent, peer-reviewed analysis from the U.S Department of Interior Bureau of Reclamation.

SSPC SP 13 NACE No. 6 Standards for the Surface Preparation of Concrete