Knit Line Techniques

Dispense Techniques for Cure-in-Place and Form-in-Place Gasketting

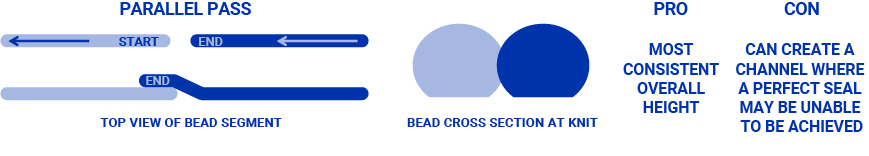

In cure-in-place (CIPG) and form-in-place (FIPG) gasketting applications, the gasket creates a seal used to protect critical components from air, dust and moisture intrusion, prevent leaking and dampen vibration. Achieving a good knit line can help to eliminate voids and ensure bead fusion to deliver a reliable seal.

Knit Line Dispense Techniques

Determining the appropriate knit line dispensing technique is an important consideration in dispense system programming and set-up. Several knit line techniques include the overlap, parallel pass, butt joint and sloping overlap.

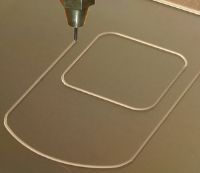

Overlap

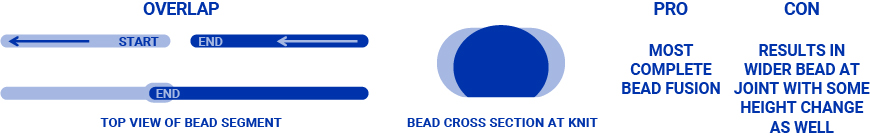

Sloping Overlap

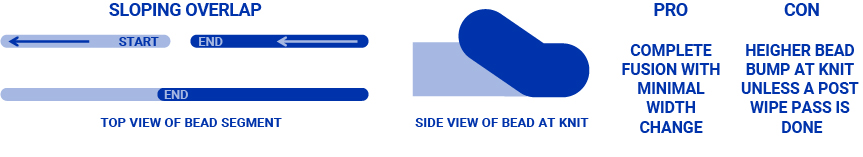

Parallel Pass

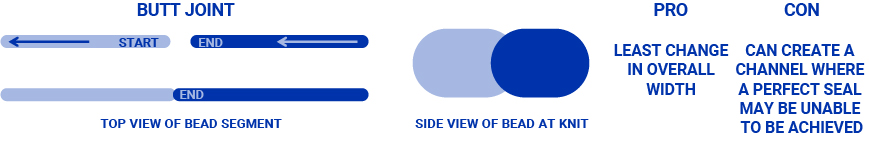

Butt Joint

Automation Techniques

Programming of the robotic dispensing system can also play a critical role in achieving bead path application requirements. Depending on the part complexity and axis, adjustments to the automation motion can help optimise the dispensing process. Several automation motion techniques include the rake motion, traditional motion, reverse rake and reverse rake and brake motion.

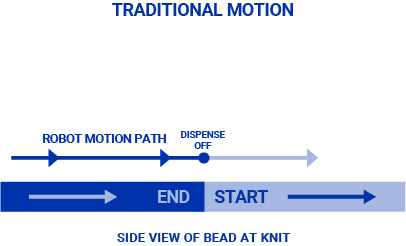

Traditional Motion

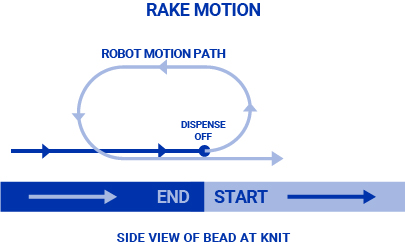

Rake Motion

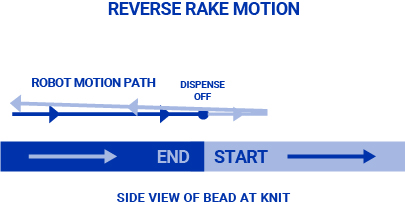

Reverse Rake Motion

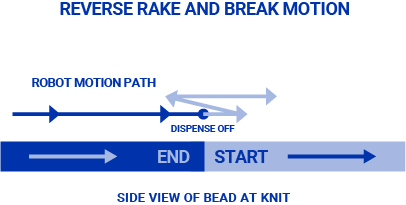

Reverse Rake and Break Motion

Summary

In CIPG and FIPG, knit line dispense techniques and automation motion techniques play a critical role in proper bead dispense and achieving the desired knit line. In addition, here are some other important considerations:

- Rheological properties of the material

- Material viscosity

- Temperature

- Bead profile and functionality

- Dispense valve sealing technology

- Dispense parameters

- Equipment fixturing

- Substrate design and complexity

Contact an Expert

Related articles

Electrifying Your Industrial Process and Grow Your Bottom Line

Electrification of industrial processes is not only good for the environment, but also makes good business sense. Explore how sustainable manufacturing leads to cost savings and competitive advantages.

Factory Keeps EV Battery Pack and Module Production Moving with Elite

Electric vehicle battery performance and safety rely on effective application of thermal interface material. TIM is known to cause production headaches on EV battery assembly lines. Learn how a large automotive manufacturer solved that problem.

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite, the longest-lasting pump construction for abrasive material dispensing.