DOWSIL™ FC-2024: Single Component Fire Protection Coating

To simplify battery fire protection, Dow Inc. developed a one-component (1K) fire and blast resistant material and then turned to Graco for an effective dispensing solution.

Single Component Fire Protection Coating

Graco’s comprehensive solution for dispensing battery fire protection material includes a Switch 3D Gun integrated with a Precision Continuous Flow (PCF) Metering and Dispensing System.

Fire and Blast Resistant Coating Protects Against Thermal Runaway

Applying fire and blast resistant coating to an electric vehicle (EV) battery pack housing offers substantial thermal and electrical protection. When exposed to extreme heat, such as during a thermal runaway event, the coating forms a ceramic barrier that prevents further damage to the battery pack and vehicle.

To enhance EV safety, Dow Inc., a leading materials science company, has developed a range of battery fire protection materials. For more about Dow silicones for battery fire protection,

- visit www.dow.com/BatterySystems

- download this product selection guide: Battery fire protection: Materials that can take the heat

Simplifying EV Battery Fire Protection

When any battery fire protection coating is sprayed over a battery pack lid, other components must be covered or masked. To reduce the need for masking, Dow Inc. developed a one-component (1K) silicone coating – DOWSIL™ FC-2024 Battery Fire Protection Coating – that can be streamed precisely, not sprayed, onto the desired substrate.

For an effective application solution for the new 1K battery fire protection material, Dow Inc. partnered with Graco.

At the Graco Customer & Innovation Centre in North Canton, OH, application lab engineers collaborated with Dow Inc. scientists and chemical engineers to determine how to evenly apply DOWSIL™ FC-2024 Battery Fire Protection Coating onto an EV battery enclosure, achieving an ideal target wet thicknesses of 1.0 to 3.0 mm, as dictated by specific battery design and protection requirements.

The testing process involved five stages:

- RHEOLOGY – Verify the material characteristics and conduct a gravity test.

- DISPENSE CHARACTERISTICS – Define the optimal equipment settings and tip configuration for the material and application.

- DISPENSE ON PANELS – Using the data collected from previous tests, apply the material on aluminium, steel and e-coated steel panels.

- VERTICAL DISPENSE – Using the data collected from previous tests, apply the material on a vertical surface

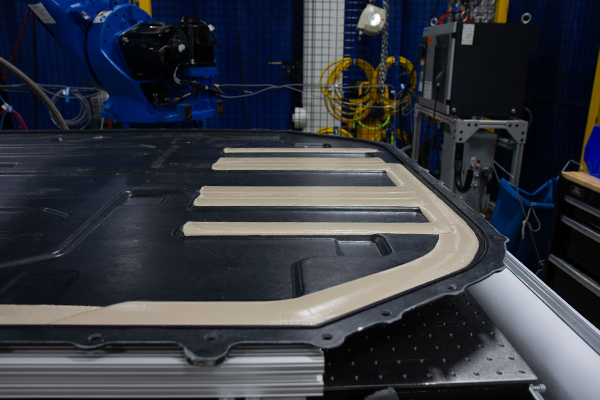

- DISPENSE ON PARTIAL BATTERY LID – An EV battery lid, made of composite, featured a deep vertical trough area, ideal for testing the vertical sag of the material.

Battery Lid Dispense

Battery Lid Trough Dispense

1K EV Battery Fire Protection Application Solution

Testing demonstrated that a Switch 3D Gun integrated with a Precision Continuous Flow (PCF) Metering and Dispensing System effectively applies DOWSIL™ FC-2024 Fire Protection Coating. The 1K fireproofing solution can consistently achieve the target thickness with an approximate maximum width of 30 to 50 mm, depending on the streaming nozzle used.

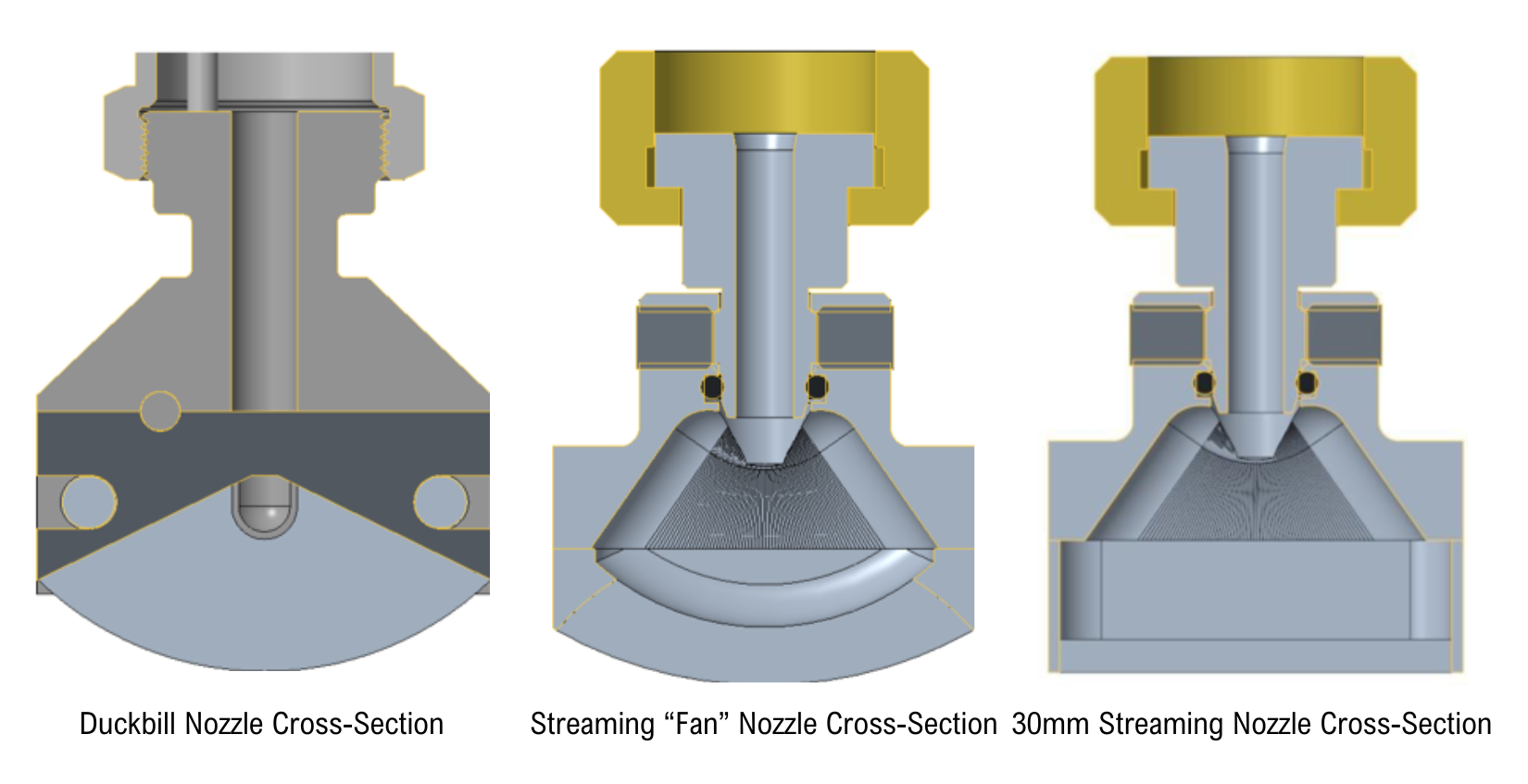

Graco engineers designed three streaming nozzles for DOWISIL™ FC-2024 Silicone Coating application.

They used computational fluid dynamics (CFD) modelling to enhance the internal architecture of each nozzle and alleviate localised shear issues that could cause rippling in the overlay of the streamed material.

All trademarks and registered trademarks are the property of their respective owners.

Contact an EV Battery Expert

We understand the complexity of battery designs and how material application influences their manufacturability. We look forward to collaborating with you to improve your battery manufacturing processes.

Recommended Products

For applying DOWSIL™ FC-2024 Battery Fire Protection Coating

Related Applications & Materials

Related Articles

Battery Pack Seal – EV Battery

A quality seal is critical for the performance and longevity of EV batteries and for protecting integral components from water intrusion and other harsh environmental conditions.

Thermal Management Benefits for EV Battery

Thermal management is critical for electric vehicle battery packs and requires durable dispensing equipment to withstand demanding application challenges.

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite, the longest-lasting pump construction for abrasive material dispensing.