Take Full Control of Your Paint Mix Room

Intelligent Paint Kitchen

Why Choose the Intelligent Paint Kitchen?

As a manufacturer, you need solutions to reduce unexpected downtime and energy costs, while maintaining a high quality finished end product.

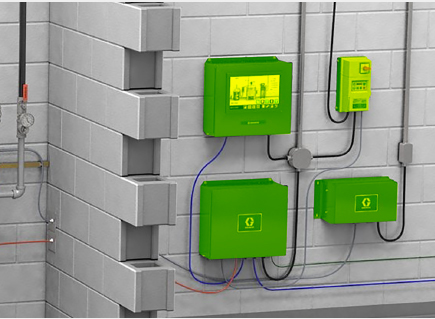

Graco’s Intelligent Paint Kitchen is a modular, easy, and cost-effective system for smart monitoring and control of your paint mix room.

- Ensure peak performance of your paint mix room with access to real-time data and critical functions.

- Manage pump pressure, flow rates, tank levels, and agitator speeds from outside the paint mix room.

The benefits of an Intelligent Paint Kitchen

Exceptional results

Optimizes the balance and performance of your paint supply and paint circulation system(s), leading to a high quality finish.

Smoother pump operation, flow, and pressure control guarantee products with a superior finish.

Consistent quality is ensured by constant pressure due to smart sensors, monitoring, and adjustment.

Control of paint flow and pressure reduces paint shear and keeps your paint in optimal condition.

Maximum efficiency

Monitors and controls pressure, flow rates, tank levels and agitator speeds to ensure your system is operating at peak efficiency.

Plug and play hardware and ready-to-use software for easy installation, configuration, operation and troubleshooting.

Start with pump control and gradually add components as needed and as your budget allows, from one to multiple stations.

Maintenance and human intervention are kept to a minimum. This makes your operation not only safer, but more efficient overall.

Advanced control

Real-time access to key paint circulation data from inside and outside the paint mix room enables quick diagnosis of issues.

Control all the tasks and functions of your paint supply and paint circulation system from outside the hazardous area via an HMI.

Can be implemented as a standalone self-controlling system or integrated with your PLC with a simple handshake.

All data can be visualized and stored, allowing you to analyze and track your complete finishing process.

Reduced costs

An inexpensive way to take full control of your paint mix room. You save on installation, operating, programming, and paint costs.

A very cost-effective way to control your paint mix room, especially compared to traditional custom-built systems.

No need for expensive programming: Just connect all the hardware, set some parameters, and you’re ready to go.

Your investment and installation costs are much lower than a custom-built system, increasing your competitiveness.

Top productivity

Ensures your paint circulation systems are operational at all times, informing you and adjusting when necessary.

The system reduces the risk of unexpected downtime, with downtime caused by maintenance kept to a minimum.

The system can run on its own and will continue to collect data and adjust accordingly, even if your PLC is down.

Connected via the internet, the system is ready for Industry 4.0 and is equipped with the technology for IoT.

How an Intelligent Paint Kitchen Works

The Intelligent Paint Kitchen is a smart set of sensors, actuators, and control modules that communicate with each other to optimize the performance of your paint supply and paint circulation system. It allows pump control (pressure and flow rates), tank control (tank levels and agitator speeds) and overall (remote) control.

Pump Control

With the Pump Control Module, you control fluid pressure and flow rates. Pump control not only keeps your pressure and flow stable and in balance, it ensures optimal paint feed to the applicators and reduces paint shear.

We're using an electric pump to visualize system setup. But the Intelligent Paint Kitchen also works with pneumatic paint circulation pumps.

Electric or Pneumatic - The Choice is Yours

- Electric -

E-Flo DC

An energy-efficient reciprocating piston pump with an electric Brushless Dual Control Motor

- Pneumatic -

Endura-Flo

Small to mid-sized double diaphragm pump that offers industry-leading flushing capabilities

- Pneumatic -

Glutton

4:1 pump that is made for tough applications and has been an industry workhorse for many years

- Pneumatic -

High-Flo

4-ball piston pump that delivers in mid-size to large circulation applications using the lowmaintenance sealed 4-ball lower

How it controls fluid pressure and flow rates

Choose between pressure, flow, and hybrid mode for both electric and pneumatic pumps.

Pressure mode

- The target fluid pressure is set in the Pump Control Module.

- The Fluid Pressure Sensors measure the fluid pressure inside the paint circulation line at the pump outlet and the back pressure regulator (BPR).

- The Pump Control Module compares the target fluid pressure with the actual fluid pressure at the pump outlet.

- The Paint Circulation Pump automatically adjusts the pressure (PID Closed Loop) to meet the pressure setpoint.

This results in steady pressure in the paint circulation line and minimal pulsing at the pump outlet.

Flow mode

- The target fluid pressure is set in the Pump Control Module.

- The Back Pressure Regulator is set to deliver the desired fluid pressure in the system.

- The Paint Circulation Pump circulates the paint at the desired flow rate, based on the volume of the pump and the position of the piston.

This results in a steady flow rate in the circulation line, while the system monitors the pressure transducers to prevent pump runaway.

Hybrid mode

- The minimum and maximum flow rates required by the circulation conditions are set in the Pump Control Module.

- The minimum and maximum fluid pressure to maintain proper spray conditions are set in the Pump Control Module.

- The system actively manages the pump pressure and flow rate to keep the system within the pressure or flow operating window.

- Changes in viscosity or the number of guns in use will cause the system to adjust the Paint Circulation Pump and Back Pressure Regulator to maintain system pressure and flow requirements.

How it keeps your pressure and flow stable and in balance

- A production and a non-production profile are set in the Pump Control Module:

- Production mode has constant pressure. The back pressure regulator (BPR) open/closed percentage is set by the user.

- Non-production mode (sleep mode) provides constant flow to keep the paint in optimal condition. The BPR is as open as possible, depending on the paint.

- The Electric/Pneumatic Transducer automatically reaches the BPR's setpoint.

- The Electric/Pneumatic Transducer adjusts the BPR, depending on the target back pressure required.

TANK CONTROL

The Tank Control Module allows monitoring and control of tank levels and agitator speeds. This keeps paint viscosity consistent, resulting in a top quality finish you can count on.

How it controls tank levels

- The tank target level is set in the Tank Control Module.

- The Radar Level Sensor measures the tank levels inside the Production Tank: the tank target level and the tank fill level.

- The Radar Level Sensor detects if the tank fill level has been reached and communicates with the Tank Control Module.

- The Tank Control Module activates the Refill Pump Solenoid, which starts up the Refill Pump.

- The Refill Pump fills the Production Tank until the tank target level is reached.

- This sequence is repeated based on the paint level changes in the Production Tank.

How it controls agitator speeds

- The Electric Agitator parameters are set:

- Minimum speed (%)

- Minimum tank level (%)

- Maximum speed (%)

- Maximum tank level (%)

- On-Off time programming

- The Radar Level Sensor measures the tank level inside the Production Tank and sends a 4-20 mA signal to the Pump Control Module and the Supervisor Box.

- The Variable Frequency Drive (controlled by the Tank Control Module and the Supervisor Box) activates the Electric Agitator.

- The Agitator will automatically slow down when the tank level is falling and automatically speed up when the tank level is rising.

OVERALL (REMOTE) CONTROL

The Supervisor Box and HMI Touchscreen allow you to remotely control the paint mix room and easily access critical paint circulation data from outside the hazardous area. This not only improves worker safety, it provides real-time information that can be used to improve the environment.

How it allows control from outside the hazardous area

- Pump and tank control settings and configurations are done via the Pump Control Module and Tank Control Module.

- All settings and configurations can also be done from outside the hazardous area via the HMI Touchscreen.

- The Supervisor Box communicates with all key Intelligent Paint Kitchen components:

- Pump Control Module

- Tank Control Module

- HMI Touchscreen

- Variable Frequency Drive (VFD)

- From outside the hazardous area, paint kitchen control and real-time access to key data are done via the HMI Touchscreen.