POLYUREA WATERPROOFING

Polyurea material is widely used in protective coating and waterproof and have a high demand in urban infrastructure (tunnel and bridge, subway and building), water conservancy engineering, petrochemical, drilling platform and other application.The Graco E-XP2 and H-XP3, electrically driven and hydraulically driven, with a maximum pressure of 3,500 psi, enabling polyurea to be sprayed more efficiently, easily and reliably.

Quick Seletion

------------- View Products-------------

Reactor2 E-XP2

Count on the Reactor 2 E-XP2 proportioner for advanced technology in applying fast-curing polyurea coatings. Because it's a Reactor 2 series proportioner, it offers software and hardware enhancements for better spray performance, plus technologies that add to your bottom line. The hybrid heater and heated hose condition the materials to the right viscosity prior to mixing. Quick knock-down lower pump for easy maintenance, easy-to-use controls, and rugged design make the Reactor the preferred choice for coatings applications.

- Quick and easy troubleshooting thanks to QR code shortcuts

- Advanced control modules

- Sacrificial surge protector

- Reactor Connect: Communication and Control at your Fingertips

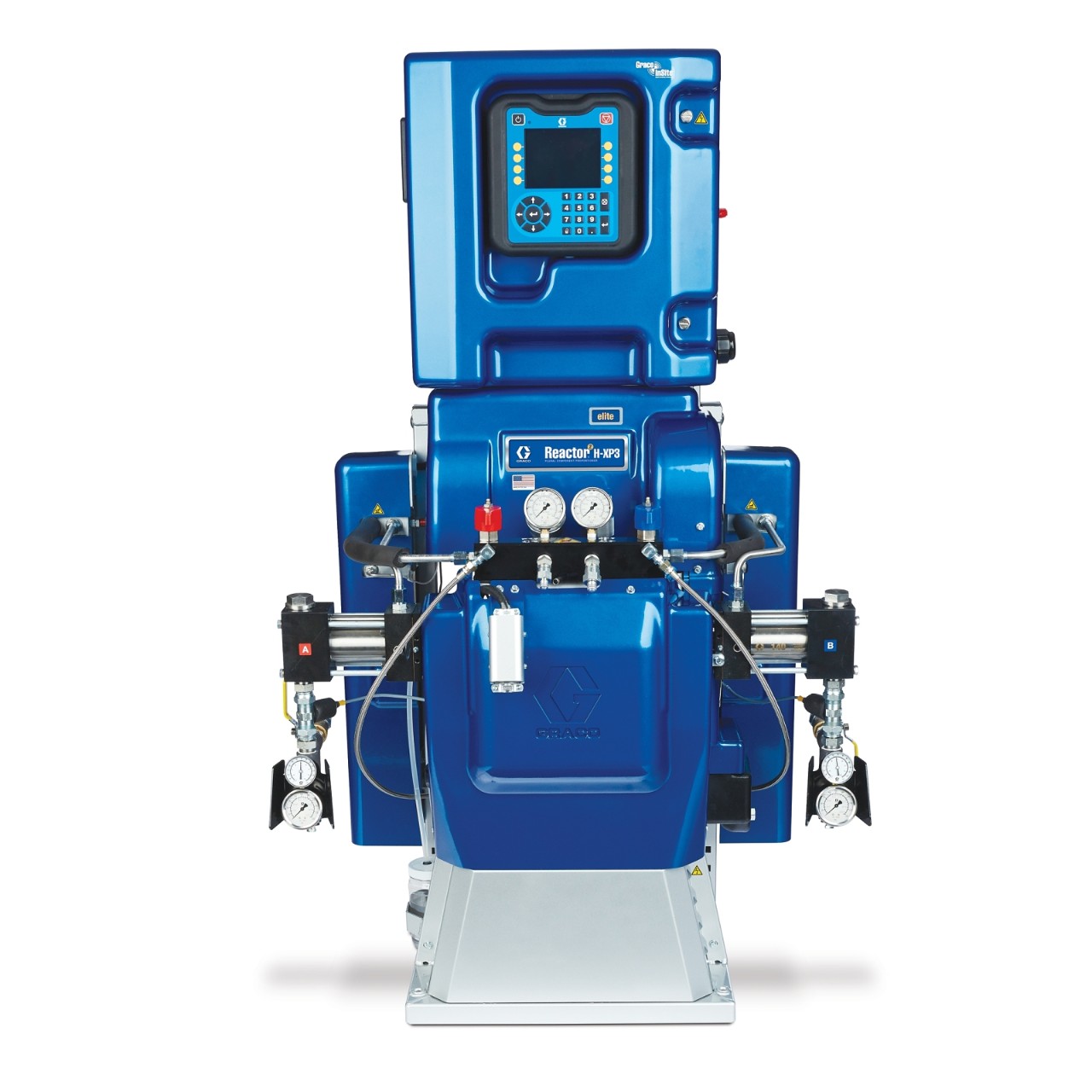

Reactor2 H-XP3

Graco's hydraulic Reactor H-XP3 brings increased yield and high output spraying. Ideal for in-plant OEMs or applicators that spray at high volumes. For coatings that require high pressures - applies up to 10.6 litres (2.8 gal) per minute.

The Reactor 2 h-XP3 is engineered to process and spray polyurea and other coatings that require high pressures. It is the next generation technology for polyurea coatings.

- Quick and easy troubleshooting thanks to QR code shortcuts

- Advanced control modules

- Sacrificial surge protector

- Advanced control technology

- Reactor Connect : Communication and Control at your Fingertips

Related articles

How to Start Up a Paint Sprayer

Proper start up of your paint sprayer is an important step to keep it running at maximum performance and efficiency, year after year.

How to Clean Up a Paint Sprayer

Making sure your paint sprayer is properly cleaned will help deliver a consistent, professional finish and a solid return on your investment.

Airless Sprayer Safety

In order to ensure a safe working environment and avoid serious injuries, make sure you completely understand all of the elements of airless sprayer safety.