Why choose an electric-driven double diaphragm pump for glue transfer?

Common Problems with Glue Pumps and How to Fix Them

| Problem | Solution | |

| The higher the viscosity, the more difficult it becomes to prime the pump. | One solution is to apply light heat to the product. This lowers the viscosity of the glue, facilitating priming and pumping. | |

| Any glue left in the pump will stick to the interior or solidify and cause a blockage. | Removing this set glue is difficult and time-consuming and could damage the pump components. It is therefore essential to keep the flow of adhesive through the glue pump or clear it out between processes to prevent issues | |

| Glue polymerises upon contact with air. | When this hardened glue circulates in the line, it can block the line or the pump, which can cause the line to rupture. A QUANTM pump can stall against pressure without additional accessories being necessary to prevent damage to the line or pump. Other electric pump technologies need additional costly accessories to prevent this from happening, such as pressure sensors, a controller, or extra equipment to create a bypass. |

An Electric-Operated Double Diaphragm Pump Has Clear Advantages Over its Air-Operated Equivalent.

Let's have a closer look.

Electric-operated double diaphragm (EODD) pumps play a big role in sustainable operations of corrugated cardboard manufacturing. Removing the costs of purchasing, running and maintaining an air compressor means significant cost savings on your operational budget.

The simple design of an EODD pump is another major advantage over other pump technologies. Simplicity of design means easier cleaning, fewer parts and faster repair, which reduces downtime of your production line.

These pumps also provide a high level of control – especially important for metering and batching. And there is no risk of contamination of products due to the absence of hydraulic backing.

An EODD pump’s seal-less diaphragm design eliminates leaking rotational seals and failures due to run-dry conditions. Other advantages include the lack of exhaust air, the ability to handle abrasives and its quietness. Making it ideal for applications in close proximity to people.

EODDs are available in several configurations that correspond to the different types of glue being used, as well as a variety of cleaning agents such as water, soda or others.

Finally, being true positive displacement pumps, EODD pumps like QUANTM pump are highly tolerant to changing degrees of viscosity of the pumped glue. This allows them to deliver constant and consistent flow regardless of back pressure.

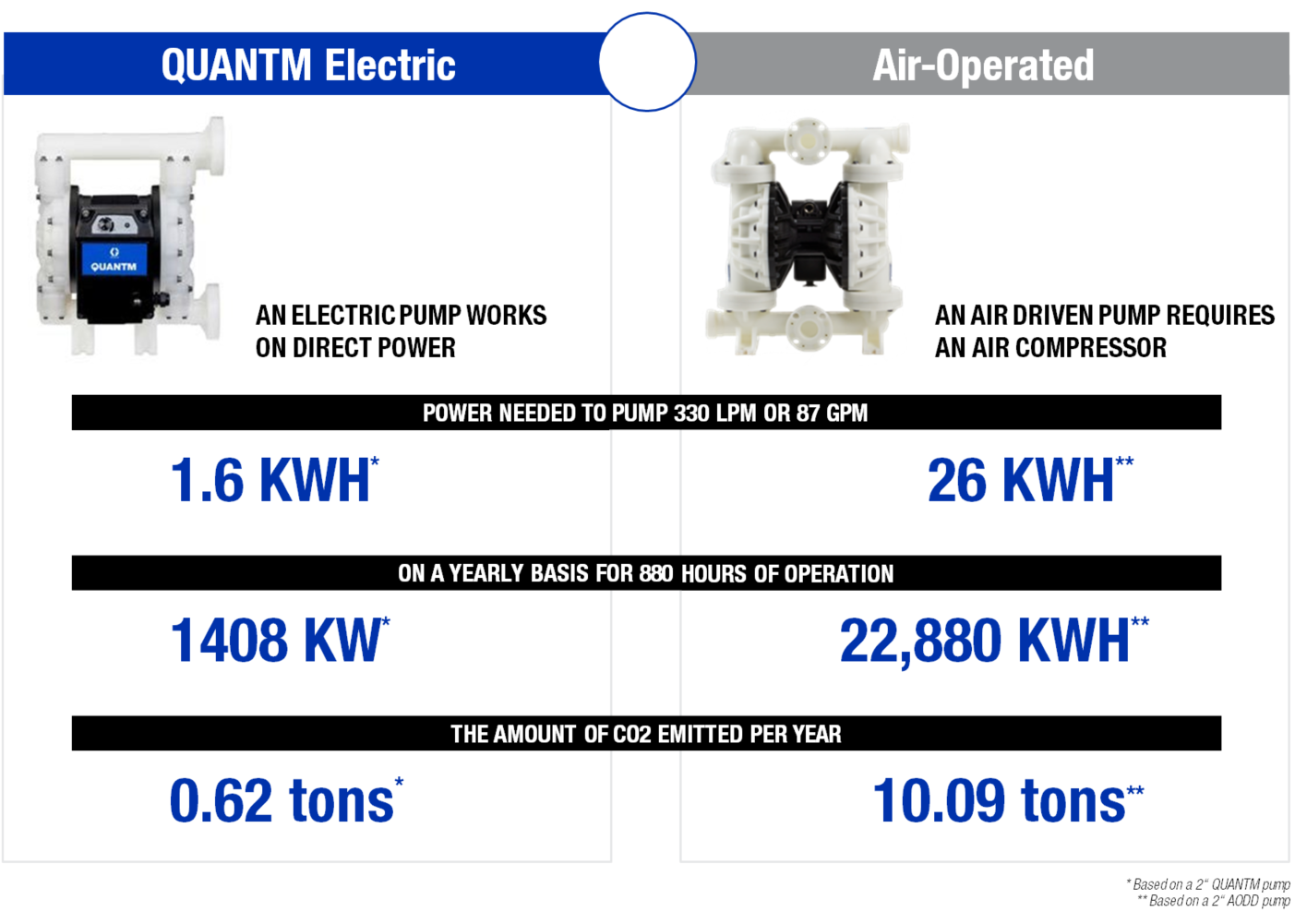

When choosing a glue pump, Graco’s QUANTM electric-operated double diaphragm pump is the preferred choice. It can stall under pressure, to prevent pump failures from clogged lines or closed valves. This is a huge benefit in a glue pump. Its energy-efficient electric drive reduces energy consumption by up to 80% when compared to an air-operated pump (AODD).

Glue pump operating costs

A 2” QUANTM pump, transferring 329 litres per minute (87 gpm) needs 1.6 kWh. If it runs for 880 hours a year, that adds up to 1480 kWh in total. Compare this to a conventional 2” AODD which consumes 75 CFM of air to have the same flow and needs a 26 kW air compressor to run. 880 hours operating time of a 23 AODD adds up to 22880 kWh in total. Huge energy savings!

Reduced energy consumption in practice

A leading UK corrugated cardboard manufacturer replaced sixty-five 2” pneumatic pumps with the QUANTM EODD for glue circulation lines in 12 factories throughout the country. The impact on energy costs and carbon reduction is significant. The energy consumption dropped from 2.37 milj to 535,000 kW/year.

Taking into consideration the elimination of the cost of compressed air and air compressor maintenance, complemented by the low maintenance costs on the QUANTM pumps their investment was paid back in less than 6 months. And not to forget that by switching to QUANTM, they reduced their carbon emissions by 80%.

Carbon Emission Comparison

Power your future and switch to electric

Cut your carbon emissions

Diaphragm pumps are a central component of manufacturing processes around the world but they need compressed air to run. Although air has historically been a reliable solution to power pumping processes, it can be very inefficient and a significant cost driver in your process. To increase efficiency and reduce operational costs, operations are constantly seeking new solutions.

Meet QUANTM

QUANTM is the next generation diaphragm pump, offering a fully-electric solution in a compact package nearly identical to pneumatic counterparts. Designed to meet the growing demand for clean energy and sustainable technologies, QUANTM pumps deliver all the well-known advantages of AODD’s while slashing energy costs and providing a quieter work environment for employees.

Choosing the right glue pump

Now that you know about the advantages that electric diaphragm pumps have over air-operated alternatives, learn about how to choose the right glue pump for your operation.

Related Articles

Choosing the Right Glue Pumps for Corrugated Cardboard Manufacturing

Double-diaphragm pumps are the preferred pumps to use as glue pumps since they are ideal for pumping high-viscosity fluids and can be adapted to the required abrasion resistance and soda concentration.

The 11 benefits of an electric diaphragm pump.

Understand the working principles of a diaphragm pump, the different types of diaphragm pumps and the common uses and applications.