Protective coatings

For every market you serve, understanding the materials, equipment and how they are affected by various operating conditions is critical to delivering a dependable, durable and on-spec finished product, regardless of the application.

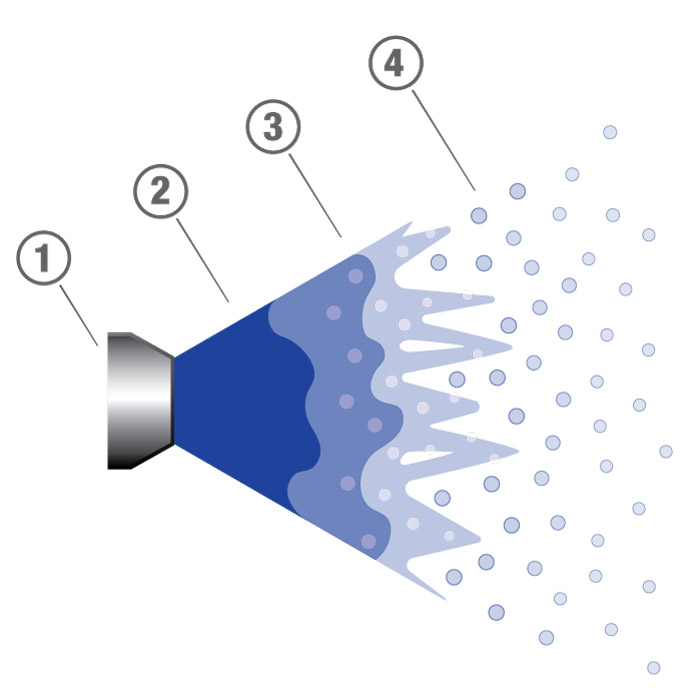

What is airless spraying?

In an airless system, fluid is pumped under high pressure through a spray tip. Instead of compressed air, the fluid itself is pressurised and the fluid becomes atomised as it passes through the spray tip.

The tip size and fluid pressure is what determines the material flow rate. The tip also creates the fan pattern. In contrast, air spray systems inject compressed air into the fluid stream of paint to achieve atomisation.

Diagram:

- Airless spray tip

- Sheet

- Disrupted

- Atomised fluid

Protective coatings articles

New plural-component sprayers deliver high-flow capabilities

Learn how the latest sprayer technology is driving labour savings, reduced maintenance and improved overall quality

How to spray inorganic zinc primers

To properly spray inorganic zinc primers, it is as much about how you handle the material as it is about the pump. Here's why.

How to Select an Airless Sprayer for Industrial Coatings

Equipment selection is critical to the successful application of industrial coatings - understand what you need to consider when choosing an airless sprayer.

How to Minimise Air Motor Freezing

Using the same basic principle as household refrigerators, air motor icing or freezing occurs when air is compressed and then rapidly depressurised.

How to Apply 500 Mils of Epoxy Material in a Single Coat

Q&A with Warren Environmental, a material manufacturer that is outfitting their approved applicators nationwide with leading edge trailers that extend the life of critical water infrastructure.